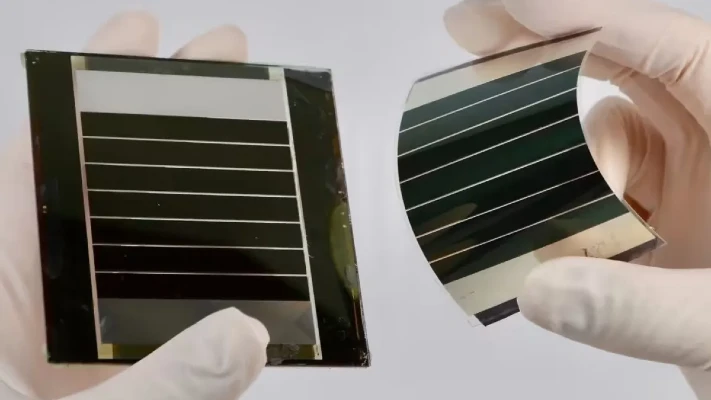

Perovskite solar cells are the rising stars of renewable energy. They have the potential to convert sunlight into electricity just as efficiently – or even better – than traditional solar panels, including those made from silicon, cadmium telluride, and copper indium gallium diselenide. But there’s a catch, slowing down their widespread use: the technology isn’t moving smoothly from the lab to large-scale manufacturing.

This ‘comfort zone’ with current methods could further slow down finding the best way to mass-produce perovskite cells.

Why the Disconnect?

Labs achieve amazing results using low-cost, “liquid ink” methods to make perovskite cells. Think of painting them onto a surface! This is fantastic for quick experimentation, but manufacturers favor a more complex technique called vapor-based deposition, similar to how some advanced computer chips are made. It’s better for mass production, but not as common in research settings yet.

“Without any doubt, the vapor-based deposition route is heavily underrepresented in research,” explains Professor Ulrich Wilhelm Paetzold of KIT.

What’s the Problem?

Mostly, cost is king. Labs can get started experimenting with the “paint-on” method for as low as $20,000. Switching to vapor-based equipment? That’s more like a $220,000 investment! Plus, the researchers themselves are already skilled in the cheaper methods, so there’s a hesitancy to switch, which is part of the problem.

“A spin coater used in solution-based methods costs $1,100 to $22,000 and a glove box, $22,000 to $65,000,” Paetzold explained. “But a thermal evaporator used in vapor-deposition processes is in the range of more than $220,000.”

Skilled labor is the other issue at play here. “If more people are skilled to do high-performance perovskite solar cells by solution processing, people tend to continue what they did before,” Paetzold says, referring to this as a “technology lock-in.”

What This Means for Sustainability

To really unleash the potential of perovskite solar, we need affordable ways to mass-produce them. It’s frustrating because we know these solar cells can work incredibly well. But until the gap between lab and factory narrows, the green energy revolution might stall.

A Brighter Future? The Race to Close the Gap

The path to mass-producing perovskite solar cells isn’t hopeless. In fact, some of the first panels could hit the market as early as this year or 2025! But for perovskites to truly transform solar power, the lab-to-factory disconnect has to be resolved. Right now, it’s a battle of techniques: will the quick-and-easy “liquid ink” method win out, the industrial vapor-based deposition, or some clever mix of the two?

“Different actors have different opinions,” says Paetzold. Since vapor-deposition is less studied, there’s room for breakthroughs that could tip the scales in its favor.

More To Discover

- UK Launches Investigation into Dove Parent Unilever’s Green Claims

- Atlantic Circulation At High Risk: Possible Collapse of Atlantic Currents Could Unleash Havoc on Europe

- They’re Transforming Discarded Bones Into Sustainable Food: Would You Eat It?

- How Nanobubble Technology is Making Giant Leaps in Sustainability and Efficiency And It’s Only The Beginning

The tricky part for industry is that current vapor-based methods are too slow for mass production. “I expect a real technology push… over the next years,” Paetzold predicts. Innovations in this area are crucial.

But there’s a bright side: if manufacturing improves, vapor-deposition could be both efficient AND cost-competitive with the “liquid ink” methods.