Amidst the hustle and bustle of the holiday season, packages of all shapes and sizes are crisscrossing the globe, bringing joy and gifts to countless recipients. However, this festive exchange comes at a price – a deluge of packaging waste, including discarded cardboard boxes and plastic-based foam cushioning like Styrofoam.

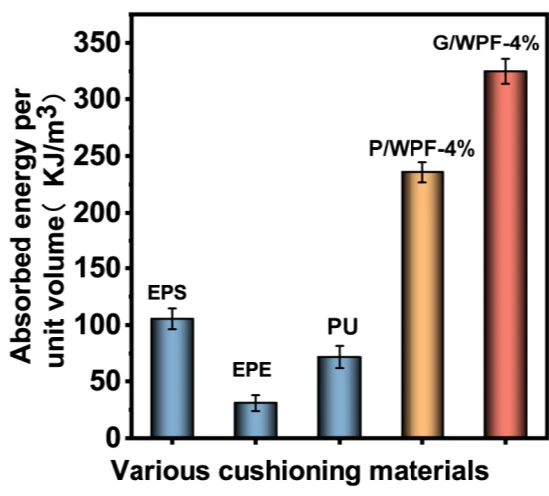

Rather than resigning these materials to the landfill, a team of researchers, as detailed in a study published in ACS Sustainable Chemistry & Engineering, has pioneered a groundbreaking approach by repurposing cardboard waste into a novel form of cushioning foam. Notably, their upcycled creation surpasses the performance of conventional plastic foam-based packaging materials in both strength and insulation properties.

Within the realm of household waste, wastepaper is an omnipresent offender. Whether it’s old newspapers, junk mail, paperboard envelopes, or cardboard boxes, these paper-based items accumulate rapidly, particularly in the era of e-commerce dominance. Researchers have long sought ways to transform this heap of paper waste into something practical – a lightweight yet durable material for shipping purposes.

Currently, the task of securing delicate items such as electronics and toys within shipping boxes often falls to molded cushioning materials, with Styrofoam being a common choice. While a sustainable alternative exists in the form of lightweight cellulose aerogels, their production from wastepaper entails numerous chemical pretreatment steps.

This complexity prompted Jinsheng Gou and his team to embark on a quest for a simpler method to craft a foam-based material from wastepaper, one capable of withstanding the rigors of the most turbulent deliveries. Think along the lines of high-quality, sustainable memory foam to protect your packages!

Their innovative foam-making process begins with the mechanical breakdown of cardboard scraps in a blender, resulting in a pulpy substance. This pulp is then blended with either eco-friendly gelatin or polyvinyl acetate (PVA) glue. The resulting mixtures are poured into molds, chilled, and subsequently freeze-dried, ultimately forming cushioning foams. Remarkably, both variants of the paper-based foam excel as thermal insulators and efficient energy absorbers, surpassing the performance of certain plastic foams.

Taking their innovation, a step further, the researchers engineered a heavyweight version of their wastepaper foam. By combining the pulpy mixture with gelatin, PVA glue, and a silica-based fluid that solidifies under pressure, they created a robust and resilient material that can be used many times over.

The team demonstrated the strength of this heavy-duty cardboard-based foam’s durability by subjecting it to blows from a hammer, without any sign of disintegration.

This impressive result suggests that the foam could even be invaluable for demanding applications, such as parachute-free airdrops of emergency services into disaster zones.

More To Discover

- Is China’s Nuclear-Powered Containership the Future of Shipping?

- A Common Laundry Detergent Enzyme Can Recycle Single-Use Plastics In 24-Hours, Researchers Discover

- Insects as a Sustainable Protein Source: A Viable Solution for Feeding a Growing Population

- Bottled Water Industry Responds to Columbia University Study on Nanoplastics & They’re Not Wrong

Jinsheng Gou and his team have unveiled a straightforward yet very effective method for repurposing cardboard waste into a more environmentally friendly packaging material. And their timing couldn’t be better!

Their work not only promises to alleviate the burden of packaging waste during the holiday season but also offers a scalable solution to the broader issue of sustainable packaging materials, ushering in a greener future for the shipping industry.