Over the last decade and a half, bamboo has emerged as a popular “eco-friendly” alternative to traditional cotton in the textile industry. Companies market bamboo as a sustainable and environmentally friendly choice, highlighting its fast growth and natural properties.

However, when we delve deeper into the entire process of turning bamboo into fiber, we uncover a different story.

This article aims to shed light on the realities of bamboo production and processing, comparing it to the familiar cotton fiber, and dispelling the myth that bamboo is a greener alternative.

The Bamboo Illusion

Bamboo is indeed a remarkable plant. It grows quickly, requires no pesticides, and can thrive in various climates. These characteristics initially make it seem like a promising option for sustainable textile production. However, the reality of bamboo manufacturing and processing unveils a more complex picture.

Bamboo Fiber Extraction

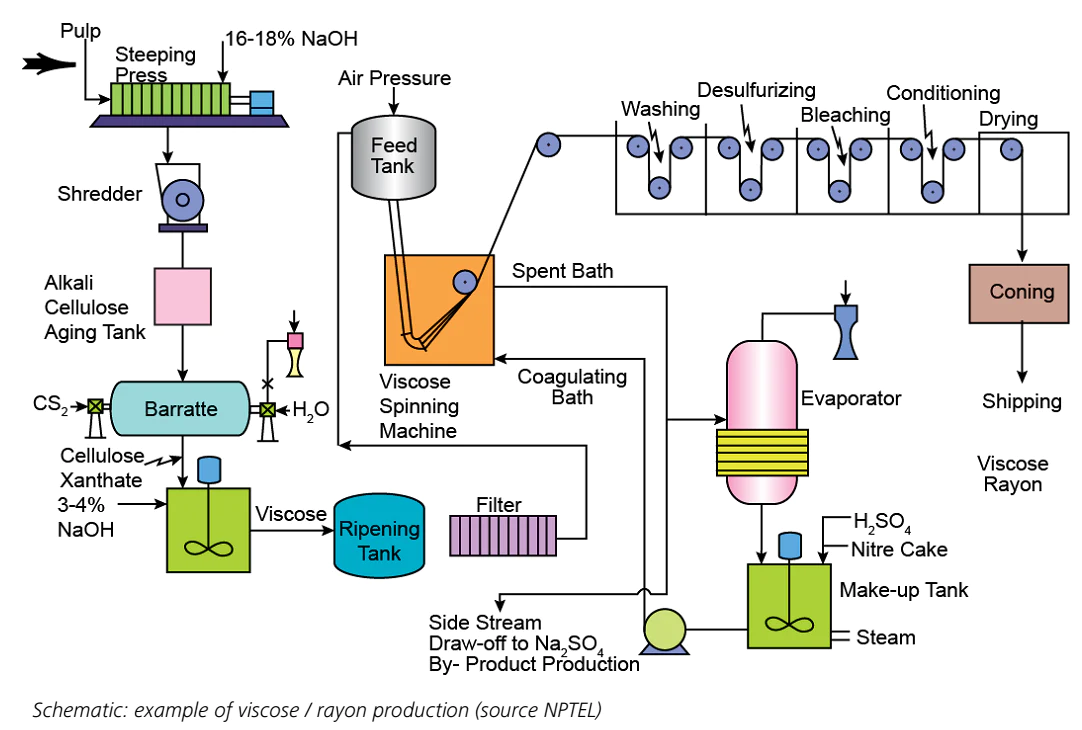

To obtain bamboo fiber, a chemical-intensive process is employed. The two primary methods used are the viscose process and the lyocell process. Both methods involve the use of harsh chemicals, such as sodium hydroxide and carbon disulfide, which have detrimental effects on both the environment and human health.

Viscose Process

In the viscose process, bamboo is dissolved in a chemical bath, creating a pulp that is then extruded into fibers. This process releases toxic chemicals into the air and water, contributing to pollution and environmental degradation.

Lyocell Process

The lyocell process is considered a more environmentally friendly method compared to viscose. It uses a closed-loop system, where the chemicals are recycled. However, this process still requires energy-intensive steps, and the final product is not always labeled as “bamboo,” but rather “lyocell.”

Energy Consumption and Water Usage

Bamboo fiber production demands significant energy consumption and water usage, just like the conventional cotton industry.

The extraction process, including pulping, bleaching, and dyeing, requires substantial amounts of water and energy.

Additionally, the transportation of bamboo from the source to manufacturing facilities contributes to the carbon footprint associated with its production.

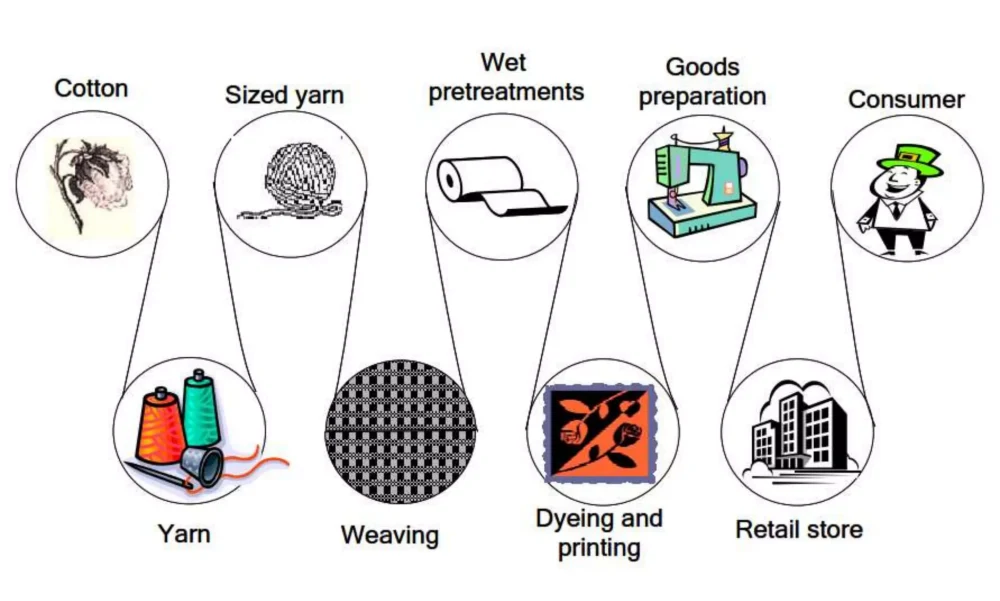

Comparing Cotton and Bamboo

While bamboo’s rapid growth and lack of pesticide use offer some advantages over cotton, the overall environmental impact of bamboo manufacturing is not significantly different.

When comparing the two fibers, you must examine the complete life cycle.

Water Consumption

Cotton is known for its water-intensive cultivation, requiring approximately 2,700 liters to produce a single cotton t-shirt. Bamboo, on the other hand, grows naturally without irrigation in some regions, making it less water-intensive. However, the intensive processing of bamboo into fiber negates this advantage, as the production stages demand substantial water usage.

Chemical Usage

Both cotton and bamboo fibers involve the use of chemicals in various stages of their production. While the viscose process for bamboo relies heavily on toxic chemicals, cotton production involves extensive pesticide and fertilizer usage, which can have adverse effects on soil, water, and local ecosystems.

Land Use

The land required for cultivating bamboo is generally less than that needed for cotton production. However, the demand for bamboo products is growing rapidly, leading to deforestation and monoculture plantations, which can disrupt natural habitats and biodiversity.

Bamboo Vs Cotton: Pros & Cons

Pros of Bamboo Fiber Production:

Fast growth: Bamboo is known for its rapid growth, which makes it a potentially renewable resource.

No pesticides: Bamboo cultivation typically does not require pesticides or fertilizers, reducing the potential negative impacts on ecosystems and human health.

Water efficiency: Some varieties of bamboo can grow without irrigation, reducing water consumption compared to crops like cotton.

Cons of Bamboo Fiber Production:

Chemical-intensive processing: The extraction of bamboo fiber involves the use of harsh chemicals, such as sodium hydroxide and carbon disulfide, which can have harmful effects on the environment and human health.

Energy consumption: The processing of bamboo into fiber requires significant energy inputs, contributing to carbon emissions and environmental impact.

Water usage: While bamboo may require less water during cultivation, the processing stages of bamboo fiber production demand substantial water usage, potentially putting strain on water resources.

Pros of Cotton Fiber Production:

Versatility: Cotton is a versatile fiber that can be used for a wide range of products, from clothing to household items.

Natural and biodegradable: Cotton is a natural fiber derived from the cotton plant, and it is biodegradable, reducing its impact on waste and landfill.

Established industry: Cotton has a well-established industry with established farming practices and infrastructure.

Cons of Cotton Fiber Production:

Pesticide and fertilizer use: Cotton cultivation is notorious for its heavy use of pesticides and fertilizers, which can have negative impacts on soil, water, and ecosystems.

Water-intensive: Cotton is a water-intensive crop, requiring substantial amounts of irrigation, which can contribute to water scarcity in regions with limited water resources.

Land use and deforestation: Cotton farming often involves large-scale land use, leading to deforestation, habitat destruction, and loss of biodiversity.

By now, you’re aware that bamboo has been touted as an eco-friendly alternative for clothing due to its rapid growth and minimal need for pesticides and fertilizers. And you also know that the reality is not as green as it is often marketed to be.

The process of turning bamboo into fabric involves harsh chemicals and energy-intensive manufacturing methods. Bamboo fibers are typically processed using either a chemical-intensive viscose/rayon process or a mechanical process that requires significant energy and resources. The chemical-based process, in particular, releases harmful pollutants into the environment, posing risks to both ecosystems and human health.

Now, many people have certain socioeconomic assumptions when it comes to what we’re going to discuss next. I’m asking only that you hold judgment and conclusions until the end of this next section.

Second-Hand Shopping: A Legitimately Sustainable Choice

One of the most effective ways to reduce the environmental footprint of the fashion industry in general (bamboo included, of course) is to opt for second-hand clothing.

Thrifting, whether in local thrift stores or online platforms, is empowering as you’re directly reducing the demand for new clothing production.

So instead of buying your next shirt made of heavily processed and highly-manufactured bamboo for $50, consider buying a handful of secondhand shirts for the same price while reducing the need for additional bamboo manufacturing.

Look, the numbers don’t lie! Second-hand shopping results in enormous energy and water savings, as no additional resources are required to create new garments.

According to the World Resources Institute, recycling one ton of clothing saves approximately 3.6 tons of CO2 emissions and at least 8 tons of water. By extending the lifespan of clothing items through second-hand shopping, we can significantly cut down greenhouse gas emissions and conserve precious resources.

But… the reductions and incredible value isn’t the only reason you should try to buy secondhand when possible. The entire fashion industry is notorious for its fast-paced, disposable clothing trends, leading to a staggering amount of textile waste, and I do mean, staggering.

When clothes end up in landfills, they contribute to greenhouse gas emissions, and synthetic materials can take hundreds of years to decompose. Choosing to opt for second-hand shopping diverts clothing away from landfills, mitigating environmental harm and promoting a circular economy.

Shopping Online When You Can't, or Won't, Shop Locally

Maybe your local thrift stores don’t have what you’re looking for, or they rarely stock your size, or perhaps, you’d rather not be seen digging through the racks of secondhand clothes.

Easy solution! Order them online. Once they’re in your home, washed and put in your closet… no one will know where they came from. Of course, no one will also know how much you’re doing to benefit our environment, but that’s your call.

The thing is that the online marketplace offers a vast array of options for finding unique and pre-loved clothing from all around the world. Shopping online allows you to discover specific styles and pieces that may not be available in your local stores.

To make your online shopping experience even more sustainable, consider the following:

1. Whenever possible, try to order multiple items from the same online retailer. By consolidating your orders, you reduce the need for separate shipments, which, in turn, lowers the overall carbon footprint associated with transportation and packaging materials.

2. Seek out online platforms that prioritize sustainability in their business practices. Some online thrift stores and marketplaces focus on eco-friendly packaging and responsible shipping methods, reducing their environmental impact. Sure, there is likely to be some greenwashing involved here, but better than nothing, right!

3. Look for local sellers or sellers within your country when shopping on international platforms. Reducing the distance your items need to travel to reach you can significantly decrease transportation-related emissions.

4. When available, choose retailers that use minimal and eco-friendly packaging. Packaging made from recycled materials or biodegradable alternatives helps reduce waste and lessens your overall environmental impact.

Making sustainable choices in the fashion industry is crucial for the well-being of our planet. By understanding the true environmental impact of bamboo clothing and embracing second-hand shopping, we can collectively reduce the harmful consequences of fast fashion. Choosing to shop second-hand, whether locally or online, allows us to decrease our contribution to landfill waste and lower greenhouse gas emissions.

More To Discover

- Self-Healing Leather Alternative from Fungi: Could It Be Mass-Produced for Sustainability?

- The Real Cost of Trendy Threads: What Boohoo’s Fast Fashion Is Costing the Earth

- Bamboo Biofuels: Green Power or Environmental Problem?

- Kourtney Kardashian Faces Backlash Over “Sustainable” Boohoo Fast Fashion Collaboration

The Path Towards Genuine Sustainability

While bamboo’s rapid growth and lack of pesticide use are appealing aspects, the overall manufacturing and processing of bamboo fibers raise environmental concerns.

It’s essential to critically evaluate claims made by companies promoting bamboo as the ultimate green choice for textiles. True sustainability in the fashion industry requires a comprehensive approach that considers the entire life cycle of materials, including cultivation, processing, and disposal.

Instead of solely relying on bamboo or cotton, exploring alternative fibers such as organic cotton, hemp, linen, or recycled materials can offer more sustainable options.

Prioritizing reduction in consumption, recycling, and promoting circular economy principles will contribute to a genuinely sustainable future for the fashion industry.

By understanding the complexities and limitations of bamboo as a textile fiber, we can make informed choices and demand genuine sustainability from the companies we support.