In a groundbreaking shift that could redefine the landscape of renewable energy, the floating wind industry is steering away from traditional designs toward an innovative future. Imagine wind turbines, not as the towering giants anchored to the sea floor you’re used to, but as seafaring carousels, gracefully spinning with blades that circle around a vertical axis.

This isn’t a scene from a futuristic novel, but the reality of what the U.S. Department of Energy’s Sandia National Laboratories is developing—a wind turbine without a tower.

Unveiling the Potential of Offshore Floating Wind

The concept of a towerless wind turbine isn’t just a flight of fancy; it’s a project years in the making, with roots stretching back to vertical axis technology research from the 1970s.

When the Energy Department called for innovative, cost-reducing floating wind turbine designs in 2019, Sandia’s team was poised with an answer: the ARCUS project. This 22-megawatt concept turbine targets an overlooked opportunity in floating wind technology, which traditionally costs significantly more than its onshore counterparts.

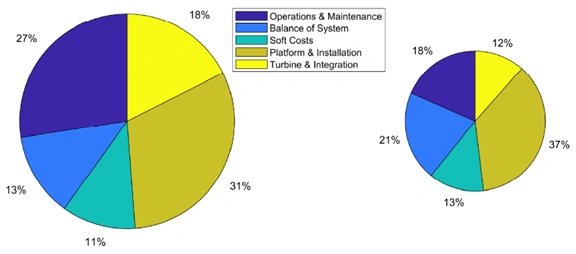

Sandia’s analysis unveiled a striking insight: in floating wind farms, the turbine itself only represents 20% of the total cost, with the remaining 80% consumed by the complex systems required for a floating platform.

This realization prompted a deeper exploration into reducing the non-turbine related expenses, a quest that could potentially revolutionize the cost structure of offshore wind energy.

The Vertical Axis Advantage

Why a vertical axis, you might wonder? The answer lies in the innovative thinking of Sandia’s researchers, who recognized the unique benefits of vertical axis turbines for floating applications.

Traditional horizontal axis turbines demand tall towers to prevent blade contact with the ground, necessitating a hefty structure for the nacelle where energy conversion occurs.

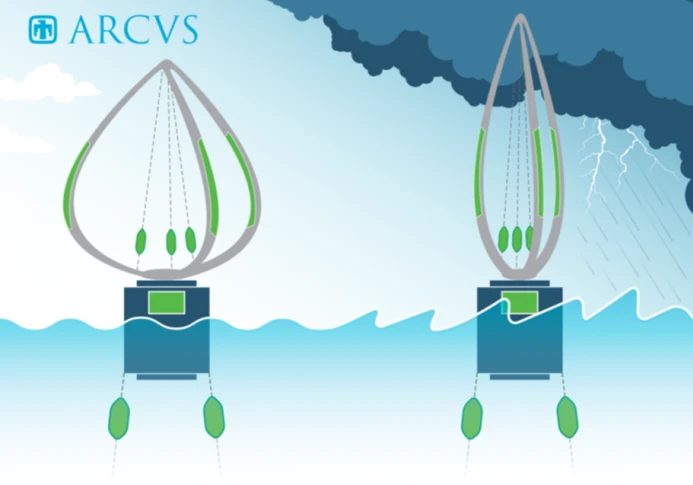

In contrast, vertical axis turbines, with their ground-sweeping blades absent, can afford shorter, lighter towers. The drive train’s placement at the base further stabilizes the structure against the ocean’s whims, streamlining aerodynamics in the process.

Dr. Brandon Ennis of Sandia’s Wind Energy Computational Sciences Department highlighted the synergy between vertical axis turbines and tension leg platforms—a type of platform borrowed from the oil and gas industry. This innovative pairing not only reduces mass and cost but also leverages decades of offshore platform advancements for wind energy.

Ennis pointed out that removing the turbines was the most obvious step forward.

The Disappearing Tower

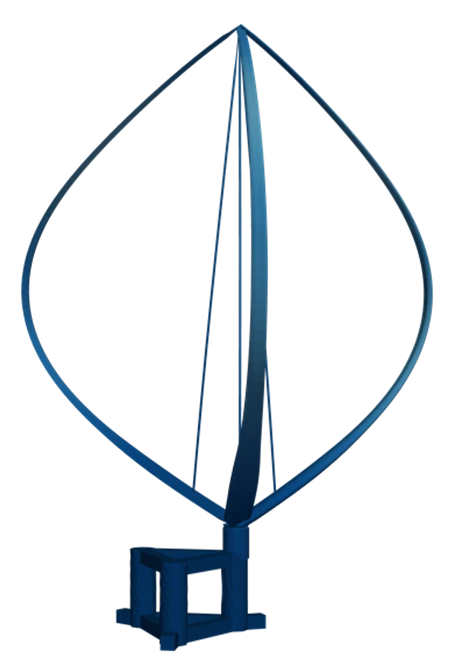

The most radical departure in the ARCUS project is the elimination of the tower altogether, a move inspired by the Darrieus turbine design, affectionately nicknamed the “eggbeater” for its unique blade movement.

This design choice cuts the turbine’s mass in half by removing non-energy producing components, a stark contrast to conventional models. “In a towerless vertical axis wind turbine, the blades are bent and held in position by tension. This produces a 50% mass reduction and allows for rotor area control through tension centers, like a bow and arrow,” explained Ennis, revealing the thoughtful engineering behind ARCUS’s design.

Pioneering a New Era of Offshore Wind

Sandia’s recent unveiling of the ARCUS project, complete with a detailed webpage and a U.S. patent, marks a significant milestone. The project’s benefits are numerous, from structurally efficient material use to enhanced control over rotor area, promising a dramatic reduction in the levelized cost of energy (LCOE) to an estimated $55/MWh. This figure not only undercuts current offshore wind costs but also positions ARCUS to accelerate the floating wind industry’s maturity by a decade or more.

More To Discover

- Solar Farms Are Killing Pollinators And Burning Bees Alive

- Indonesian Court Just Gave 65,000 Acres of Indigenous Ancestral Forests to a Palm Oil Company

- From High Hopes to Bankruptcy: The Rise and Fall of Braddock’s Vertical Farming Pioneer, Fifth Season (Our Analysis Included)

- Stanford Engineers Slash Energy Use by 97% with Ingenious Actuator

The collaboration with industry partners like FPS Engineering & Technology and the American Bureau of Shipping underscores the project’s potential impact. By combining innovative design with strategic partnerships, ARCUS is poised to transform offshore wind energy, making it more accessible, affordable, and efficient than ever before.

As the world stands on the cusp of a renewable energy revolution, the work of Sandia National Laboratories and its partners shines as a beacon of innovation and sustainability. The towerless wind turbine isn’t just a technological marvel; it’s a testament to human ingenuity and our collective pursuit of a cleaner, greener future.