The quest for environmentally friendly solutions in our everyday products has recently turned its gaze towards an unexpected ally: seaweed. Amid the ongoing discussions about sustainability and reducing carbon footprints, a remarkable initiative out of Norway has emerged, promising to revolutionize the furniture industry. This initiative, spearheaded by a Norwegian company named Agoprene, proposes seaweed as an eco-friendly alternative to the foam rubber commonly used in furniture.

The journey to this innovative solution begins with Celine Sandberg, the founder and CEO of Agoprene, who has roots deeply embedded in entrepreneurship, tracing back to her great-great-grandfather, Nils Halvorsen Norheim.

Norheim was a pioneer in his own right, establishing the first automated flatbread factory in Norway back in 1919. A century later, Sandberg, inspired by her family’s legacy, embarked on a mission to tackle a pressing environmental issue: the substantial carbon footprint of polyurethane foam rubber.

“In the furniture industry, everyone knows that foam is bad for the environment and no one wants to use it, but there are no other alternatives. I want to supply [a more sustainable] alternative to what we have today, with no petrochemicals,” explained Sandberg.

This material, prevalent in sofas, chairs, and other furnishings, is notorious for its environmental impact, producing around 105 million metric tons of CO2 emissions annually. Sandberg, driven by the urgency of the situation and the lack of eco-friendly alternatives in the furniture industry, sought to create a sustainable solution that would not only reduce dependency on petrochemicals but also pave the way for a greener future.

Despite having a background in business development and finance rather than engineering, Sandberg’s academic pursuits at the Norwegian University of Science and Technology’s School of Entrepreneurship inspired her to delve into the realm of material technology.

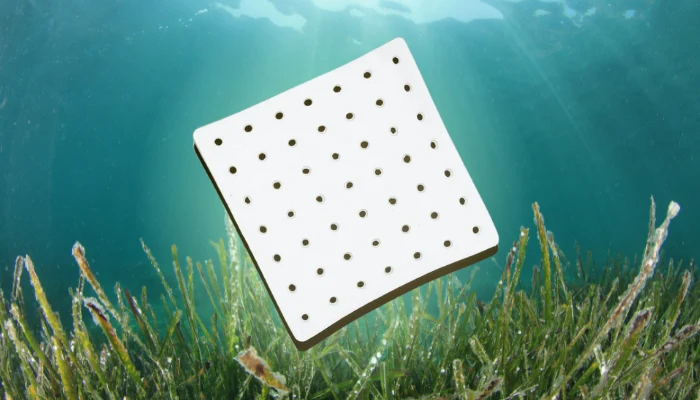

Her research led her to the potential of using biomass as an alternative to petroleum-based products, eventually zeroing in on seaweed as a viable and abundant resource along Norway’s extensive coastline.

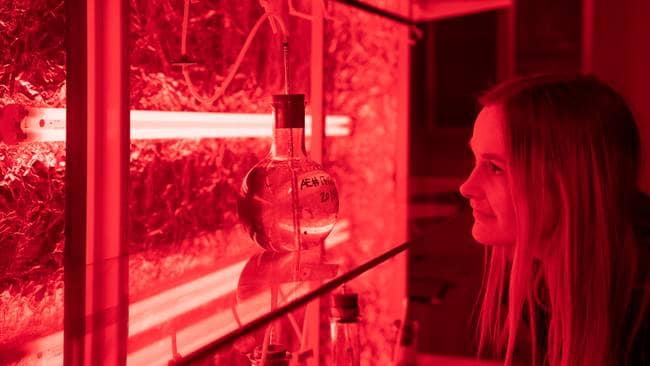

Sandberg, alongside Agoprene’s research chemist Asanga De Alwis, began experimenting with various seaweed-based materials, enduring a trial-and-error process that produced around 800 foam samples. Their dedication and perseverance, fueled by a modest budget from the Research Council of Norway, eventually paid off.

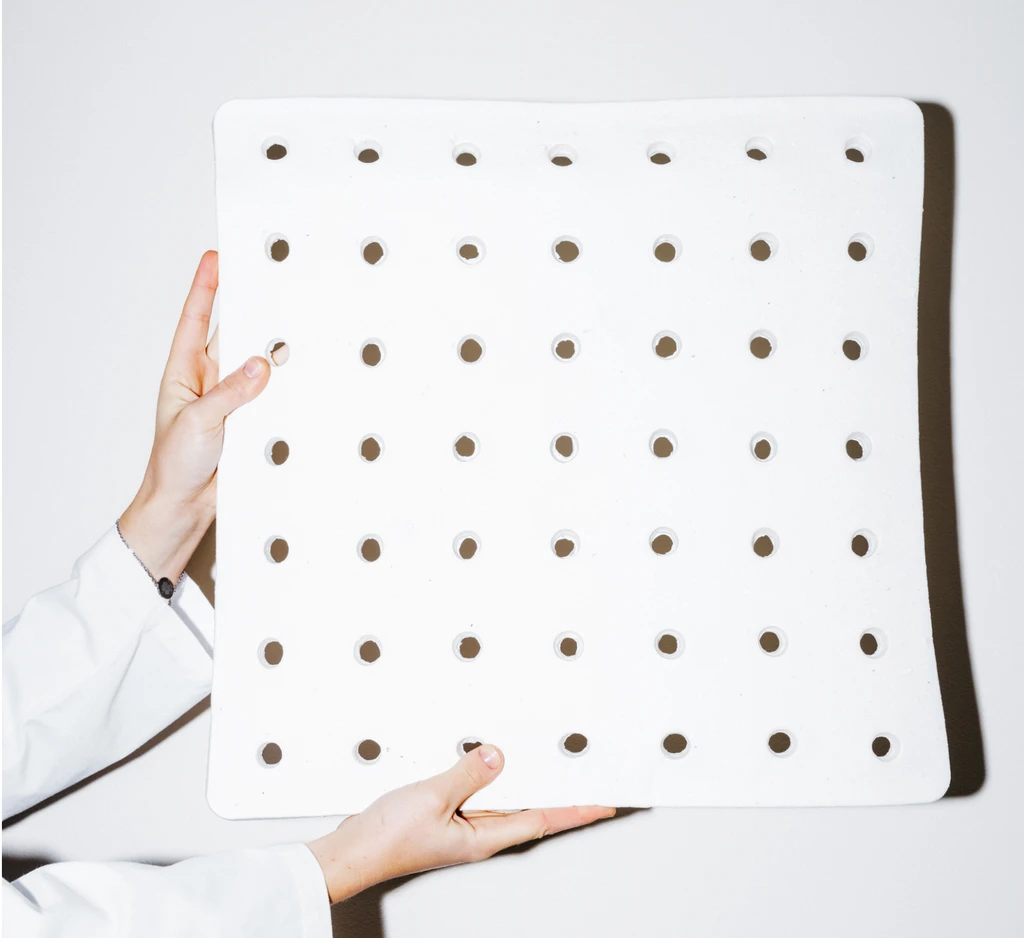

Agoprene’s innovative approach involves a method reminiscent of baking, where seaweed-based mixtures are molded and heated to form sustainable foam – a biofoam, if you will. This process, while challenging, has the potential to significantly reduce the environmental impact of furniture manufacturing.

The company’s efforts were recognized in 2023 when it was selected to join the BioInnovation Institute’s Venture Lab acceleration program. This support has enabled Agoprene to pilot the production of 500 foam pillows and explore the scalability of their methods.

With aspirations to launch their product by the end of 2023, Agoprene isn’t only focused on transforming the furniture industry but is also exploring other applications for their sustainable foam, including inquiries from ski manufacturers, soundproofing companies, and shoemakers.

“At the moment, we are focused on developing foam for furniture, but we are also open to exploring new applications,” Sandberg says.

Sandberg’s vision extends beyond Agoprene’s success. She aims to inspire a movement towards sustainability in material technology, encouraging more startups to develop eco-friendly alternatives to petrochemicals.

Despite the challenges associated with bio-based materials, Sandberg hopes that Agoprene can foster a community dedicated to tackling environmental issues collectively.

“In Scandinavia, there aren’t many people working with bio-based materials, as it’s so challenging. I hope Agoprene can create a community of sorts, inspiring others to come together to tackle the problem. I want more people to do what we do,” Celine stated with growing optimism.