Researchers have developed a groundbreaking self-heating concrete that integrates phase-change material, capable of melting snow and ice autonomously for up to 10 hours, eliminating the need for harmful salt or laborious shoveling. This pioneering material heralds a potential shift away from traditional snow and ice removal methods, promising to safeguard road integrity and reduce maintenance costs.

In the United States, the Department of Transportation highlights that over 70% of the nation’s roads traverse snowy regions where ice and snow accumulation pose significant hazards. These conditions not only diminish road friction and vehicle control, leading to increased accident risks, but also clog lanes, extending travel times and reducing road efficiency.

Annually, local and state agencies allocate upwards of $2.3 billion for snow and ice control operations. This figure doesn’t account for the millions more spent repairing damages inflicted on infrastructure by these wintry conditions. Traditional preemptive salting, while effective against ice formation, has a corrosive effect on concrete and asphalt surfaces. Furthermore, water infiltration into roadways, followed by freezing, exerts internal pressure that can severely damage the pavement.

A team from Drexel University in Pennsylvania—a state no stranger to cold weather challenges—has introduced their self-heating concrete solution, aimed directly at addressing these perennial winter woes.

The Cost of Winter Maintenance: A Salty Dilemma

The continuous cycle of freezing and thawing, exacerbated by salting, compromises the structural integrity of road surfaces, leading to early deterioration. Amir Farnam, the principal investigator at Drexel’s Advanced Infrastructure Materials (AIM) lab and a leading author of the study, emphasizes the sustainability angle of their innovation. “One way to extend the service life of concrete surfaces, like roadways, is to help them maintain a surface temperature above freezing during the winter,” Farnam explains. By reducing reliance on plowing and salting, this technology not only protects the concrete but also presents an environmentally friendly approach to managing winter roads.

The ‘special material’ at the heart of this innovation is paraffin, known for its phase-change properties, which allow it to release heat as it transitions from liquid to solid with falling temperatures. Initially proven effective in controlled lab settings, the real breakthrough came when the material demonstrated its capabilities under the rigorous conditions of an actual winter, marking a significant step towards practical application.

Self-Heating Concrete Paves the Way for Safer Winter Roads

In an innovative leap forward, researchers have developed self-heating concrete slabs capable of tackling snow and ice accumulation without the need for corrosive salts or back-breaking shoveling. This breakthrough comes as part of a rigorous testing phase aimed at offering a sustainable solution to winter road maintenance challenges.

The Experiment Unveiled

The Drexel University team employed two innovative techniques to embed paraffin, a phase-change material known for its heat-release properties, into concrete. The first method involved soaking lightweight aggregates—components added to concrete for strength—in liquid paraffin before mixing into the concrete. Alternatively, the second method mixed micro-capsules filled with paraffin directly into the concrete mix.

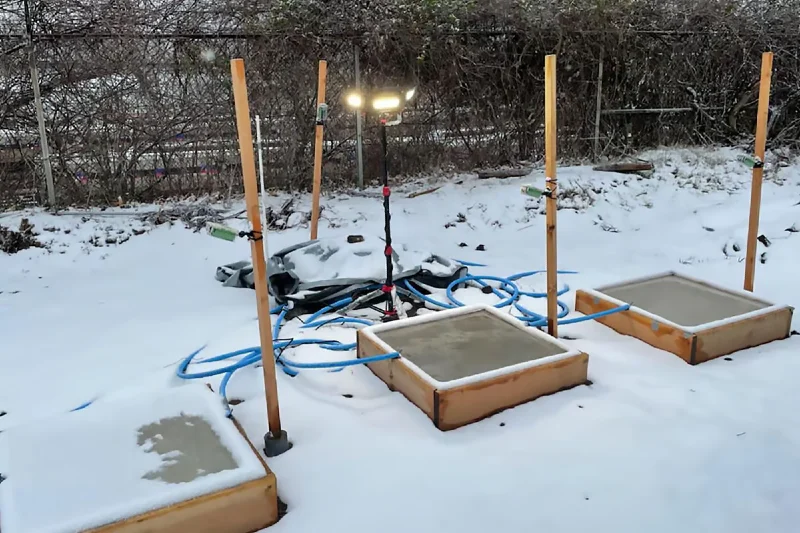

Three slabs were laid out for testing alongside a parking lot on the university’s campus since December 2021, subjected to the harsh winter conditions of 32 freeze-thaw cycles and five substantial snowfalls. Equipped with cameras and thermal sensors, the slabs’ ability to combat ice and snow was put to the test.

Results That Warm the Heart (and Roads)

The results were promising. The concrete embedded with phase-change material exhibited the ability to maintain surface temperatures between 42°F and 55°F for up to 10 hours under freezing conditions, effectively melting snow at a steady rate.

“We have demonstrated that our self-heating concrete is capable of melting snow on its own, using only the environmental daytime thermal energy – and doing it without the help of salt, shoveling or heating systems. This self-heating concrete is suitable for mountainous and northern regions in the US, such as Northeast Pennsylvania and Philadelphia, where there are suitable heating and cooling cycles in winter,” stated Amir Farnam.

This innovation is particularly suitable for regions prone to heavy snowfall and freezing temperatures, offering a glimpse into a future where roadways autonomously keep themselves clear of winter’s icy grasp.

A Closer Look at Performance

Among the two methods, the slab using lightweight aggregate showed a superior ability to sustain heat, likely due to its porous nature, allowing the paraffin to remain liquid and release heat gradually. This contrasted with the micro-capsule method, which heated quickly but for a shorter duration.

Robin Deb, the study’s lead author, emphasized the importance of preventing freeze-thaw cycles, which compromise road integrity through expansion and contraction.

“Freeze-thaw cycles, periods of extreme cooling – below freezing – and warming, can cause a surface to expand and contract in size, which puts a strain on its structural integrity and can cause damaging cracking and spalling over time. And while this alone may not degrade the structure to the point of failure, it creates a vulnerability that will lead to the problematic interior deterioration that we need to avoid. One of the promising findings is that the slabs with phase-change materials were able to stabilize their temperature above freezing when faced with dropping ambient temperatures,” said Deb.

The slabs with phase-change materials were able to maintain temperatures above freezing, suggesting a significant reduction in structural stress and potential damage.

Limitations and Future Directions

The study did reveal limitations, such as reduced effectiveness under heavy snow accumulation beyond two inches and the need for the material to ‘recharge’ between weather events. Despite these challenges, the research team is optimistic about refining this technology to extend concrete’s lifespan and enhance its deicing capabilities.

However, sustainability concerns linger regarding the source of paraffin, a petroleum byproduct, pointing to the need for further exploration of environmentally friendly alternatives.

As this pioneering study, published in the Journal of Materials in Civil Engineering, progresses, it stands as a testament to the potential for integrating phase-change materials into infrastructure, promising roads that not only withstand the rigors of winter but also contribute to a more sustainable future.

More To Discover

Concluding Thoughts

The journey towards integrating self-heating concrete into our roadways is an exciting frontier in the fight against winter’s hazards. This technology not only promises to make roads safer, but also paves the way for more sustainable practices in maintaining our infrastructure.

“With these findings, we will be able to continue to improve the system to one day optimize it for longer heating and greater melting,” Deb affirmed. “But it is encouraging to see evidence of significant reduction of freeze-thaw cycles, which demonstrates that PCM [phase-change material] concrete is more freeze-thaw durable compared to traditional concrete.”

As research continues, the hope is to refine and optimize this system, making icy roads a concern of the past and ushering in a new era of smart, self-sufficient roadways.