Leather’s got style, no doubt about it. But let’s face it, the way we’ve been making it? Not so great for the planet. Enter the world of fungi – not just for your pizzas anymore! Scientists are now turning these mushrooms into a leather-like material. And guess what? It’s awesome for the environment.

To be clear, we’re not talking vegan leather here! This isn’t made from oil-based plastics masquerading as somehow superior to a byproduct that feeds people.

Mycelium Magic

Mycelium, the root-like structure of fungi, is our hero here. This stuff can grow into a material that feels a lot like leather. It’s like nature’s own craft project. Senior Scientist Géza Szilvay from VTT says they’ve been experimenting with this in the lab, and the results are like a high-five to the environment.

Szilvay from VTT notes, “In laboratory conditions, fungal mycelium can be used to rapidly produce material with a feel and tensile strength akin to animal skin.”

This process not only offers an eco-friendly alternative but also uses organic waste as raw material, epitomizing the principles of a circular economy.

The researchers cultivated mycelium in a nutrient-rich solution, forming a thick skin that, once dried, and treated, resembled leather without compromising the chlamydospores’ vitality. This process not only increased the material’s durability but also created a rather unique, and surprising, feature unseen in traditional materials: the ability to self-repair.

Here’s the cool part: some products made from this fungal leather are already out there. But, there’s a catch – scaling up. It’s like trying to make your grandma’s secret recipe for a whole wedding when you’ve only ever cooked for two. VTT is on it, though, working on taking this to a mass-produced scale.

Self-Healing Leather? Yep, You Heard That Right

Over in the U.K., some smart folks at Newcastle and Northumbria Universities are taking it up a notch.

They’ve created a type of material that can heal itself! Got a tear? No problem. This stuff can patch itself up. It’s like having a leather jacket with its own repair kit built in. Just imagine the damage self-healing, legitimately sustainable fungi leather could have on the colossal, and horrifying, fast fashion industry!

This material retains the natural ability of fungal chlamydospores to regenerate, offering a self-healing property when exposed to conducive environments.

A Peek Into the Leather Industry

Leather has been a cornerstone of fashion and utility for centuries, but its production process raises several environmental concerns. Traditional leather production involves tanning, a process that often uses chromium, a heavy metal that can be harmful to both the environment and human health. The tanning process releases pollutants into waterways, impacting aquatic life, and has even been known to enter the human food chain.

Yet, when we look at the bigger picture, traditional leather does have some points in its favor compared to synthetic, oil-based alternatives.

Natural leather, in essence, is a byproduct of the meat industry. This means it utilizes materials that would otherwise go to waste, adding a layer of sustainability. In contrast, synthetic leathers are typically petroleum-based, contributing to fossil fuel depletion, a high carbon footprint, and releasing toxic emissions during production.

However, these advantages don’t fully offset the environmental footprint of traditional leather. The key concerns include the vast amounts of water used in tanning, energy consumption, and the use of harmful chemicals. These aspects not only contribute to pollution but also lead to significant greenhouse gas emissions.

Despite the challenges, the leather industry has been making strides towards more sustainable practices. These include adopting vegetable tanning methods, which use natural tannins instead of chromium, and implementing water recycling processes to reduce consumption and pollution. Some tanneries are also exploring renewable energy sources to lower their carbon footprint.

The conversation around leather sustainability is complex. On one hand, traditional leather utilizes a natural byproduct and, if produced responsibly, can have a lower environmental impact than its synthetic counterparts… not to mention, people get fed. On the other hand, the industry still faces significant challenges in reducing its ecological footprint.

In this context, the emergence of sustainable alternatives like fungal mycelium leather is particularly exciting. It offers a potential pathway to reduce reliance on both traditional and synthetic leathers, paving the way for a more sustainable future in materials science.

So, Can We Mass Produce This?

That’s the billion-dollar question. Can we take this awesome lab discovery and turn it into something we see in stores everywhere? It’s challenging, sure. But if we can pull it off, we’re looking at a future where fashion meets sustainability in a big way.

At this point, the researchers need only one main thing… money, and a lot of it! Taking research such as this and turning it into a viable, mass-produced success story available in stores worldwide is expensive and right now, investors aren’t exactly lining up. Perhaps if the researchers changed the name to something like Mycelium AI?

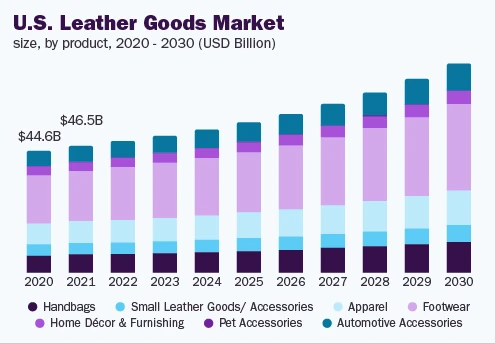

Snark aside, though, the global leather industry is worth over $242 billion and grows roughly 5% a year. That’s a lot of potential right there!

More To Discover

- Hyped Tech-Driven Solutions to Climate Change Are Falling Short

- Setback for US Offshore Wind Ambitions as Orsted Halts Major Projects Citing Economic Pressures

- Pet Tech Privacy Issues: The Hidden Risks in Your Smart Pet Gadgets

- Upcycled Cardboard Foam Outperforms Plastic, Paving the Way for Sustainable Shipping

Wrapping It Up: Fungi Fashion for the Future

In a world where we’re all trying to be a bit kinder to our planet, this fungal leather is like a breath of fresh air. It’s stylish, sustainable, and has the potential to make a real impact. So next time you’re thinking about leather, remember self-healing fungi might just be the future. And until then, we always have the more fragile mushroom leather on the market right now, along with a strong new sustainable contender – pineapple.