The future of eggs is undergoing a remarkable transformation, ushering in an era where traditional egg-laying flocks may become a thing of the past. This groundbreaking shift is happening right now.

In recent decades, egg production has witnessed an astonishing surge, nearly doubling in volume. To put it in perspective, if current projections hold, we are poised to witness the production of a staggering 138 million tons of eggs by the year 2030, equating to an astounding 2.3 trillion eggs annually.

However, this exponential growth in egg production isn’t without its challenges, as the egg ingredient market faces a period of significant change characterized by stricter requirements, supply chain vulnerabilities, and limited alternative solutions.

The importance of eggs can’t be overstated.

Their versatility and widespread use as a primary source of animal protein have solidified their place in the global food manufacturing landscape.

Eggs serve a multitude of purposes in food production, ranging from binding and thickening to coating and leavening, not to mention their role in emulsifying and foaming.

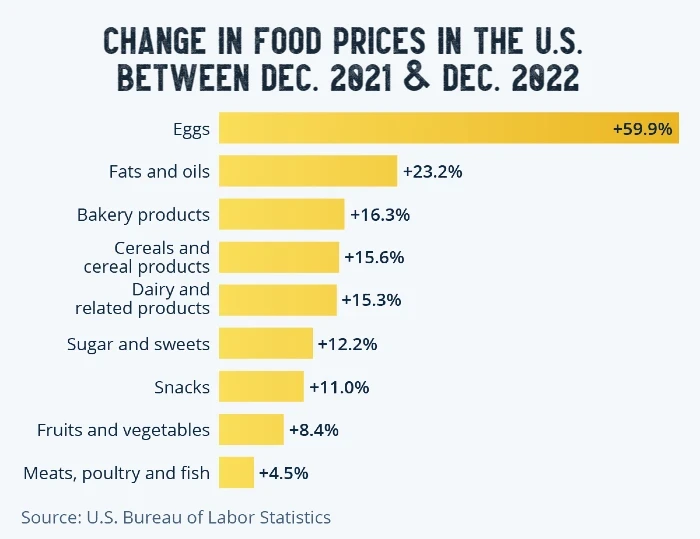

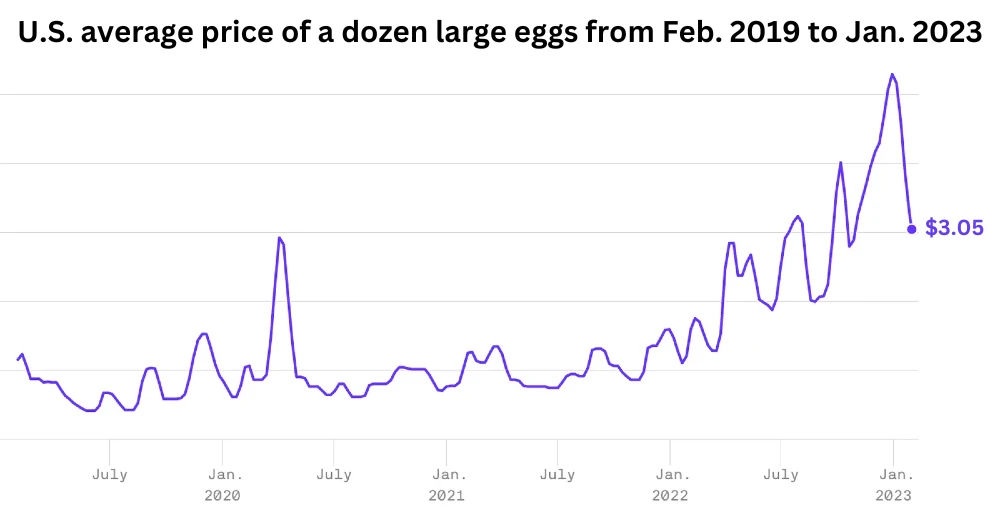

A recent phenomenon known as “egg-flation” has sent shockwaves through the industry, resulting in a staggering 70% increase in egg prices between 2020 and 2023, as reported by the Bureau of Labor Statistics.

This surge can be attributed to a combination of factors, including higher costs of chicken feed and a devastating outbreak of bird flu that disrupted the egg supply chain.

The avian flu outbreak, which wreaked havoc in the United States alone, led to the loss of approximately 50 million birds and incurred economic losses estimated at up to $3 billion. Furthermore, the egg production industry struggled to meet its commitments to transition towards cage-free production, exacerbating the crisis.

The repercussions of factory chicken farming extend far beyond the economic sphere. It exacts a heavy toll on the planet, manifesting as excessive land use, loss of biodiversity, environmental pollution, greenhouse gas emissions, and water scarcity.

These profound environmental impacts, coupled with the susceptibility of avian flu to trigger potential human pandemics, underline the urgent need to seek a more sustainable solution to meet the world’s insatiable demand for eggs.

The Future of Flocks: Fermentation Leading the Way

In our diets, egg protein plays a crucial role, but the traditional practice of raising laying hens might soon take a back seat to a groundbreaking alternative: fermented eggs.

Advances in technology and a resurgence in precision fermentation are reshaping the world of food production, making it possible to craft delicious, functional food items like eggs without relying on animals. Talk about a win-win-win! This approach has huge benefits for the planet, human health, and animal welfare alike.

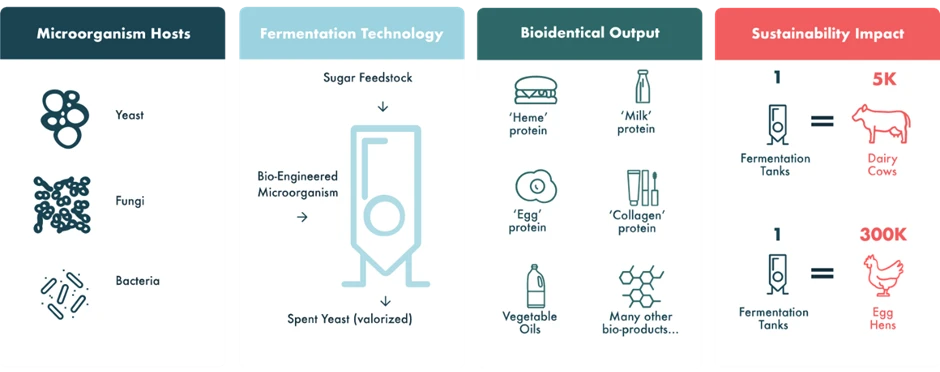

Precision fermentation is an emerging food technology that leverages microorganisms to generate specific functional food components, some of which have traditionally been sourced from farm animals.

The underlying methodology of precision fermentation draws parallels with the brewing of beer and has been employed for approximately half a century to produce food essentials such as vitamins, flavors, enzymes (e.g., rennet), and even pharmaceuticals like insulin.

Only recently has it been adapted to produce high-volume ingredients for the food industry. Within this field, scientists are exploring the use of a forest-dwelling fungus called Trichoderma reesei, which has been trained to synthesize egg protein instead of its natural enzymes.

A significant breakthrough in this field is the development of Bioalbumen, the world’s first animal-free ovalbumin protein, corresponding to the primary protein found in egg whites. This innovation offers a nature-identical alternative to ovalbumin, the key protein responsible for most of the functional properties of eggs.

This powdered marvel can seamlessly substitute egg white powder and even whole eggs in culinary recipes, all without harm to chickens or any feathers being ruffled.

Egg protein produced through precision fermentation not only enhances cost-efficiency but also slashes the environmental footprint by a staggering 90% in comparison to traditional egg production methods while still delivering the same high-quality protein.

Fermentation techniques also bolster yield, amplifying production by a factor of 10. To put this into perspective, one kilogram (equivalent to 2.2 pounds) of Bioalbumen powder can yield the egg white equivalent of a whopping 277 eggs.

These efforts are not isolated; numerous companies are embracing precision fermentation for food production.

Many are already acquainted with Impossible Foods and its heme protein, responsible for creating a plant-based Impossible Burger that closely (according primarily to vegetarians who have not tasted beef in a decade) mimics the taste of beef.

The Every Company produces an ovomucoid protein utilized in baking, beverages, and various food products. Perfect Day specializes in whey protein produced through precision fermentation, and New Culture has pioneered animal-free casein for cheese production.

To ensure the safety of these precision fermentation-derived products for human consumption, several have already secured FDA clearance, while others are in line to receive a “No Objections Letter” in the coming year.

This letter signifies that the FDA acknowledges the ingredient’s safety for consumption in food products, meeting the GRAS (generally recognized as safe) standards.

Moreover, on a global scale, various organizations are actively collaborating to devise resilient and sustainable solutions for our food system.

The Precision Fermentation Alliance has been established to serve as a unified voice and a global platform for the precision fermentation industry, while Food Fermentation Europe fulfills a similar role in the European context. These endeavors collectively represent a commitment to shaping a more sustainable and adaptable food landscape for the future.

The Future of Precision Fermentation: A Turning Point

This is the era perfectly suited for animal-free ingredients. It’s happening at a moment when humanity’s collective awareness of the climate and food crisis has reached a critical juncture.

Simultaneously, industrial biotechnology methods have matured to a point where, with the aid of microorganisms, proteins can be efficiently produced on a massive scale.

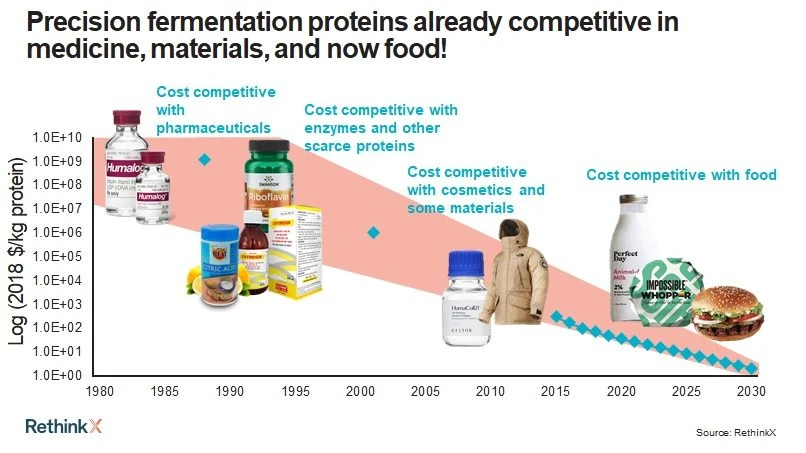

A production system like Trichoderma has showcased remarkable performance over decades, particularly in the enzyme industry on an industrial scale. This achievement paves the way for scaling up food ingredient production to meet industrial demands and rapidly achieving market price parity.

Furthermore, numerous innovations have been introduced and patented within the Trichoderma production system to ensure exceptional product quality at a global standard.

Precision fermentation for food ingredients leverages industry-standard equipment and well-established practices from the industrial enzyme sector. This lends transparency to the pricing of the product compared to its animal-derived counterpart.

We have a clear understanding of the necessary manufacturing facility requirements and how to design the production unit processes. The challenge now lies in adapting this knowledge to food manufacturing and ramping up production to meet the colossal volumes required.

There is a tremendous appetite among food manufacturers for fermentation-based egg protein. The problem exists, and now there is a solution.

The remaining steps revolve around execution.

Consumers are increasingly open to the concept of egg ingredients derived from fermentation, particularly as they become more acquainted with the product’s advantages.

The prospect of developing the egg industry without the need for chickens presents itself as a clever, achievable, and well-justified component of the green transition.

A recent study conducted by the Hartman Group in partnership with Cargill and Perfect Day highlights that four out of every ten consumers are inclined to purchase food produced through precision fermentation.

This openness prevails even when adults aren’t well-versed in precision fermentation and lack a description of its meaning; 41% would still buy a product produced using this method.

When adults are familiar with the technology and have access to a description on product packaging, this likelihood surges to a remarkable 80%.

Interestingly, safety holds a slightly higher priority for consumers than taste when it comes to products made through precision fermentation.

Three out of five consumers prioritize safety as their primary concern, emphasizing the importance of ensuring the safety of these innovative products.

While taste remains a key factor, with 52% stating that products from precision fermentation should have a superior taste for regular consumption, the emphasis on safety underscores the growing acceptance of this technological method in food production.

Numerous companies are harnessing precision fermentation to develop ingredients that are gradually entering the market. Additional studies also affirm that consumers are more willing to embrace food created through this technological method when they’re well-informed about its nature and purpose.

Insights into Precision Fermentation: A Sustainable Culinary Revolution

In the realm of food innovation, many precision fermentation companies have transitioned from the experimental stage to a level of expertise and scale capable of supplying ingredients to food manufacturers.

For instance, Perfect Day, a collaborator in this research that is now valued at $1.5 billion, has successfully incorporated its animal-free dairy ingredients into a range of products, including milk beverages, cream cheese, ice cream, and chocolate bars.

What sets precision fermentation apart from other alternative proteins is that the resulting ingredients are virtually indistinguishable from the items they replace.

This cutting-edge technique utilizes biotechnology to re-engineer common microbes, such as yeast, to produce proteins or substances that are identical to those typically found in foods like eggs, dairy, or sweeteners when subjected to fermentation.

The Good Food Institute aptly describes precision fermentation as a means of transforming microbes into “cell factories” capable of producing large quantities of something new.

Despite the seemingly complex nature of producing food through such a scientific method, consumer studies have consistently shown that people are open to these possibilities, provided they receive some education about the products and the production methods involved.

Consumers are recognizing the environmental strain caused by our current food system and are more inclined to act, and that’s backed up by real data.

In fact, a study by the Hartman Group has shown that nearly seven out of ten individuals believe society must discover ways to fulfill nutritional needs while consuming fewer resources.

Moreover, 61% of respondents identify science and technology as our best hope for addressing climate change.

While precision fermentation itself has been in use for years – notably in the production of rennet used for cheese-making for over two decades – many of today’s startups employing this method have emerged out of environmental concerns and the pressing need for more sustainable food production.

According to a third-party life cycle assessment of Perfect Day’s animal-free whey protein, it consumes between 96% and 99% less water and 29% to 60% less non-renewable energy compared to traditional whey production.

More To Discover

- Green Energy Breakthrough: South Korean Researchers Pioneer Algae-Based Hydrogen Production

- Setback for US Offshore Wind Ambitions as Orsted Halts Major Projects Citing Economic Pressures

- Transforming Palm Trees into Eco-Friendly Building Materials: A Green Innovation to Tackle Construction Emissions

- Bitcoin Miners Triumph in Court, Shielding Energy Secrets. Why It Matters.

Interestingly, when consumers were educated about the environmental benefits of products derived from precision fermentation, purchase intent increased by approximately 30% for both products traditionally sourced from animals and stevia produced through precision fermentation.

These insights do show that it’s important for companies that are using precision fermentation to communicate their stories and highlight the taste and nutritional quality of their products.

Recently, nine industry leaders formed the Precision Fermentation Alliance, a trade group dedicated to promoting understanding and transparency of the technology.

A unified message and concerted efforts in consumer education can go a long way in advancing the adoption of these sustainable and innovative food production methods.

Inarguably, precision fermentation represents a promising avenue for addressing the pressing issues of sustainability, climate change, and resource conservation in our food system.

With growing consumer awareness and the concerted efforts of industry players, it holds the potential to revolutionize our approach to food production and pave the way for a more sustainable future.