In an era where the planet’s waste crisis escalates with each passing day, a beacon of innovation emerges from the heart of Stellar3. Co-Founder, CEO, and President, Dan Nienhauser, stands at the forefront of this revolution, steering the company towards a future where landfill waste morphs into sustainable fuel. The imminent launch of the world’s first commercial ‘no burning’ waste-to-energy plant isn’t just news; it’s a paradigm shift in how we perceive and manage waste.

Our world produces a daunting 2 billion tons of waste annually, a figure that starkly highlights the magnitude of the global waste dilemma. This waste, predominantly ending up in landfills, carries more than just an environmental cost; it seeps into the very bloodstream of humans and animals, ushering in a slew of potential health crises.

Nienhauser prompts us to expand our understanding of waste’s impact, urging a shift from local to global perspectives on waste management.

Stellar3’s Leap With Thermal Chemical Conversion Technology

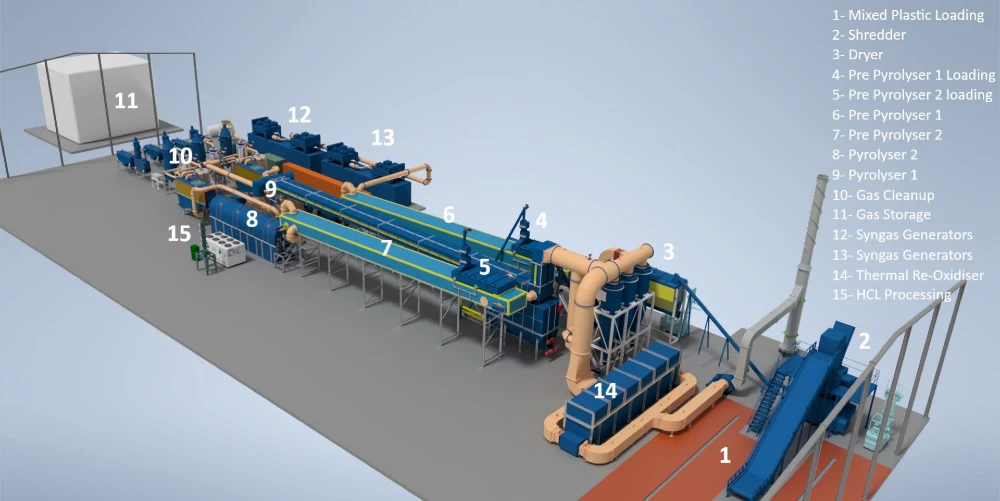

At the heart of Stellar3’s mission lies its patented Thermal Chemical Conversion technology, a novel approach that sees landfill detritus—ranging from municipal solids and mixed plastics to expired tires—as treasure troves of syngas, low-carbon liquid fuels, circular pyrolytic oil, recycled carbon-black, and even electricity.

This technology doesn’t just aim to reduce waste; it aspires to redefine it, transforming what was once considered refuse into valuable resources.

Dan Nienhauser clarifies this vision, stating, “Our goals are to change the perception around waste being waste and recognize that waste is energy.” It’s a bold assertion that underscores Stellar3’s commitment to a circular economy, where waste is not an endpoint but a beginning.

A Future Forged in Pyrolysis

The company isn’t stopping with a single plant. Over the next six years, Stellar3 envisions erecting many waste transformation facilities, each playing a pivotal role in saving approximately seven million tons of CO2 equivalents in its initial phase. The long-term vision is even more audacious, aiming to mitigate a hundred million tons of CO2 equivalents over a decade.

This ambitious plan is grounded in Stellar3’s modern take on pyrolysis—a process of decomposing organic material at high temperatures in the absence of oxygen. Despite its century-old roots, Stellar3’s pyrolysis process is anything but antiquated. It represents the culmination of a decade’s advancements, offering a scalable, efficient method to convert a variety of waste into valuable commodities without extensive facility overhauls.

The Dawn of a New Era in Waste Management

With Stellar3’s commercial plant slated to launch in the upcoming weeks, Dan Nienhauser’s excitement is palpable. He envisions a future where waste transformation technology not only mitigates the global waste crisis but also redefines the essence of waste itself. “We have science that has now started to help us change the word waste,” he reflects, envisioning a world where waste is viewed not as a burden but as a bountiful source of raw materials and energy.

Financial Innovations in Waste-to-Energy: A Comparative Insight

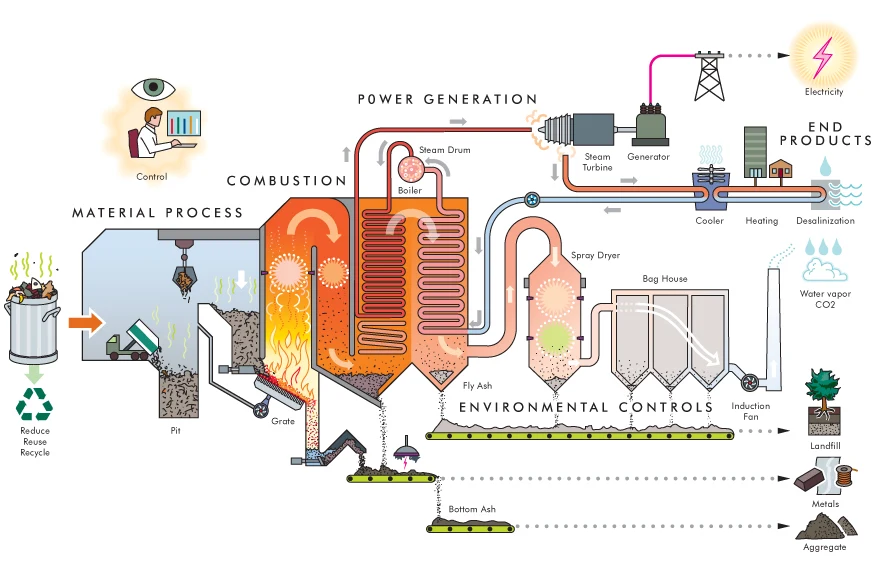

The financial landscape of waste-to-energy (WTE) technologies is as diverse as the technologies themselves, reflecting a range of capital and operational expenses. Traditional WTE plants, typically reliant on incineration, have long been critiqued for their high initial capital costs and operational expenses, coupled with environmental compliance costs. These plants usually require significant investment in pollution control equipment to mitigate emissions, adding to their overall financial burden.

In contrast, the advent of ‘no burning’ technologies, like the Thermal Chemical Conversion process developed by Stellar3, represents a potential shift in the economic paradigm of waste-to-energy solutions. While exact figures for Stellar3’s commercial plant aren’t readily available (and those that have been provided previously are now outdated and unreliable), the financial appeal of this process and technology is multi-faceted:

- Reduced Operational Costs: By avoiding incineration, ‘no burn’ plants potentially lower operational costs related to fuel consumption and emissions control. The process of thermal chemical conversion, operating in the absence of oxygen, may also lead to more efficient material conversion rates, thereby optimizing fuel output from the waste input.

- Capital Investment: The initial investment in ‘no burn’ technologies can be variable, heavily influenced by the scale of the operation and the sophistication of the technology used. However, the modular nature of some of these plants, as suggested by Stellar3’s approach, could allow for scalable investments, enabling smaller initial outlays with the option to expand capacity as demand grows.

- Comparative Costs: Traditional waste-to-energy plants have seen their costs increase over time due to stricter environmental regulations and the need for advanced emission control technologies. In comparison, ‘no burn’ technologies, designed with modern environmental standards in mind from the outset, might offer a more stable or even reduced cost profile over time. This is because they inherently produce fewer pollutants, potentially reducing the need for expensive emission control systems.

- Revenue Streams: Beyond the cost considerations, ‘no burn’ plants like Stellar3’s might also benefit from diversified revenue streams. The ability to produce not just energy but also valuable byproducts like syngas, low-carbon liquid fuels, and recycled carbon-black could enhance financial viability. This diversification, uncommon in traditional WTE plants, may offer a competitive edge in the market.

- Market Comparisons: While traditional WTE projects often struggle with profitability without government subsidies or incentives due to their high operational costs and environmental concerns, ‘no burn’ technologies may carve out a niche by capitalizing on their lower environmental impact and potentially lower costs, appealing to both investors and regulatory bodies.

While specific financial data for Stellar3’s pioneering ‘no burn’ waste-to-energy plant remains undisclosed, the broader economic landscape suggests that such innovations could significantly disrupt the traditional WTE market.

By potentially offering lower costs, reduced environmental impact, and diversified revenue opportunities, ‘no burn’ technologies represent a compelling financial proposition in the quest for sustainable waste management solutions.

More To Discover

- Greenwash Update: Checking In On Coca-Cola and Starbucks’ Previous Environmental Claims

- The Future of Eggs Is Here: Precision Fermentation Means Flocks Won’t Need To Produce Eggs

- Texas A&M Researchers Explore Black Soldier Fly’s Potential in Tackling State’s Manure Issue

- Bill Gates-Backed Bioscience Firm Will Release a Vital Palm Oil Substitute Called Palmless

Stellar3’s journey is more than just the story of a company. It’s a testament to human ingenuity’s power to tackle some of our era’s most pressing challenges.

As the first ‘no burning’ waste-to-energy plant prepares to go online, it stands as a beacon of hope—a tangible example of what’s possible when innovation meets environmental stewardship. In this new chapter of waste management, Stellar3 isn’t just transforming waste; it’s reshaping our very relationship with the planet.