In the quest for a greener planet, the energy industry faces significant hurdles. While advancements in electric vehicles, solar and wind energy, and energy-efficient homes are making headway, two major challenges persist: developing scalable long-term energy storage and decarbonizing heavy industries such as steelmaking. The solution to these critical issues could transform the clean energy landscape and create new economic opportunities.

A Game-Changing Discovery

Enter Form Energy, a Massachusetts-based green energy company that has stumbled upon a groundbreaking solution while addressing long-term energy storage. Form Energy’s innovative ‘ iron-air’ battery, designed to store clean energy for extended periods, has inadvertently found a way to clean up the iron and steel industry, one of the biggest carbon emitters globally.

How the Iron-Air Battery Works

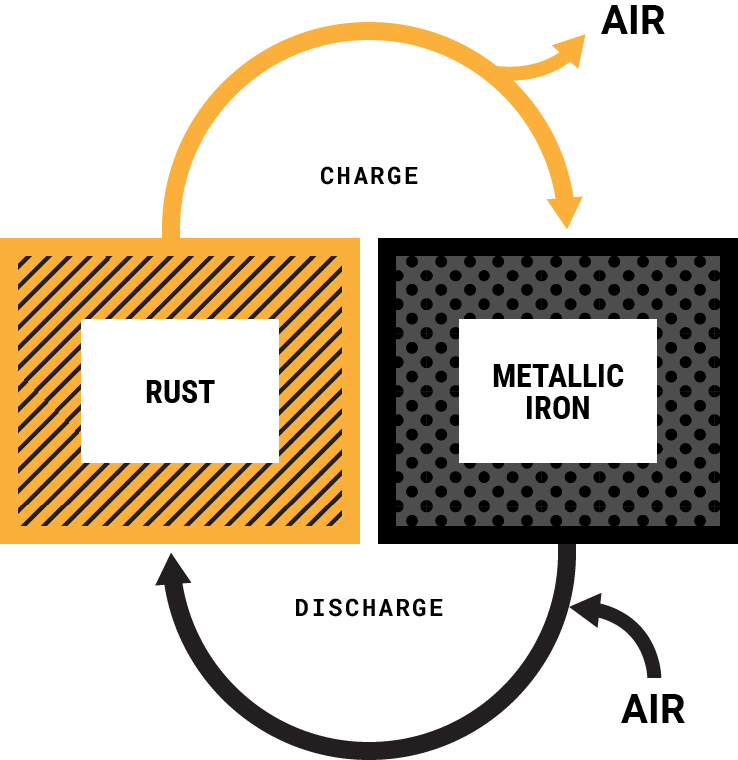

The iron-air battery developed by Form Energy stores energy by converting rust into pure iron. When energy is needed, the battery reverses the process, turning iron back into rust and feeding energy back into the grid. This cycle not only provides a scalable solution for energy storage but also presents a novel approach to decarbonizing steel production.

Traditionally, purifying iron ore for steelmaking is a carbon-intensive process, heavily reliant on high-emission coking coal. Steel production is responsible for at least 7% of all man-made greenhouse gas emissions, making it the largest-emitting manufacturing sector. Existing methods to reduce these emissions have fallen short of providing a comprehensive solution.

Disrupting the Steel Industry

Form Energy’s technology offers a promising alternative. By placing powdered iron ore in a low-temperature alkaline solution and running an electrical current through it, they produce powdered metallic iron. This process can be continuous and highly efficient, potentially competing with conventional fossil-fuel-powered furnaces.

Mateo Jaramillo, Form Energy’s co-founder and CEO, highlighted the economic viability of this method. “We found a cheaper, more scalable, more efficient process for producing green iron,” Jaramillo told Canary Media. He emphasized the technology’s potential to create significant value, indicating a strong commitment to its development.

Support and Future Potential

Form Energy’s clean iron initiative has garnered support, receiving funding from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) last month. The potential impact of scalable clean steelmaking technology is enormous.

As the World Economic Forum states, steel is integral to various industries, from automotive and construction to machinery and transportation. Decarbonizing steel production wouldn’t only reduce the industry’s emissions, but also significantly cut emissions in all sectors dependent on steel.

A Sustainable Path Forward

The implications of Form Energy’s discovery are profound. By addressing two major decarbonization challenges—energy storage and industrial emissions—this technology could be a cornerstone in achieving global climate goals.

More To Discover

- MIT’s Bacteria-Based Solution for Sustainable Farming May, One Day, Replace Chemical Fertilizers

- World’s Tiniest Marine Mammal Faces Imminent Extinction In First Alert Issued By International Whaling Commission

- Vanished Giant Returns: California’s Lost Lake Reemerges After 130 Years

- Heat Pumps Are Going Industrial: Big Changes, Bigger Savings Ahead

As nations continue to ramp up renewable energy production, solutions like Form Energy’s iron-air battery and clean steelmaking process offer a glimpse into a sustainable future.

In the relentless pursuit of carbon neutrality, breakthroughs like these remind us that innovation often comes from unexpected places. Form Energy’s dual-purpose technology could indeed be the key to a cleaner, greener world, marking a significant milestone in the fight against climate change.