Plastic is an inescapable reality of modern life, cluttering our planet from the deepest oceans to the highest mountains. Yet despite the bleak outlook on plastic recycling—often described as neither technically nor economically feasible on a large scale—there remains a shimmer of hope. Small-scale initiatives, such as those by mtrl.bike, are stepping up to challenge this notion by integrating recycled plastic into the circular economy, starting with an innovative product: bicycles.

The journey began in 2014 when Johannes Alderse Baas envisioned a bicycle constructed from recycled plastic. This idea, initially just a concept, has evolved significantly over the years. By 2022, what was once known as DutchFiets transformed into mtrl.bike, collaborating with igus motion plastics® to create the RCYL brand. These efforts have culminated in a prototype ready for small-scale production, with pre-orders already being accepted for these unique recycled plastic bikes.

These bikes aren’t only a step towards more sustainable transportation but also boast practical benefits. They are marketed as “almost maintenance-free,” eliminating the need for oil and resistant to rust, which could make them an appealing alternative for eco-conscious consumers.

The partnership with igus:bike aims to expand this technology, potentially allowing more companies to manufacture durable, low-maintenance bicycles using recyclable materials.

One of the standout features of mtrl.bike’s production process is its commitment to minimal environmental impact. By harnessing 100% renewable energy in the manufacturing of these bikes, the company strives to keep its carbon footprint as low as possible. This approach highlights how sustainable practices can be integrated into the production of everyday goods.

Currently, igus:bike is in the process of producing the first 100 bikes, slated to be available in the Cologne area of Germany by early 2024. Potential buyers in the Netherlands and Germany can join a waitlist through the mtrl.bike website, with prices starting at €1195 ($1,300). For those interested in staying updated, mtrl.bike and igus:bike maintain an active presence on Instagram.

How mtrl.bike’s Sustainable Design Stands Out

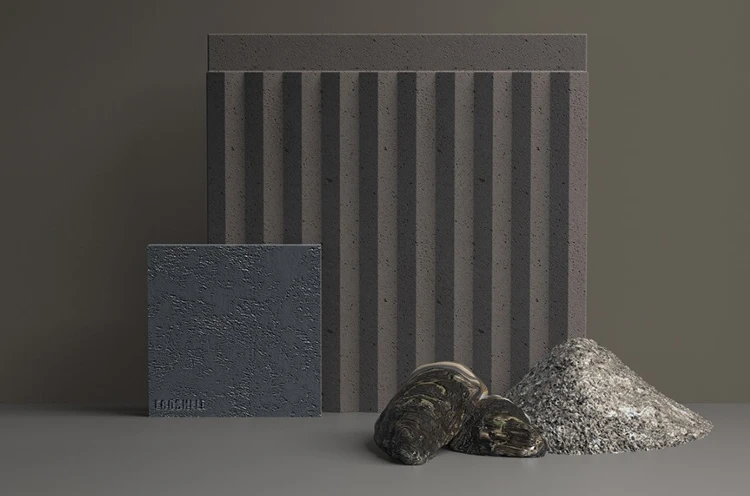

The core of mtrl.bike’s sustainability lies in its material choice and production methods. Traditional bicycles are typically made from metals, which, while durable, have a heavier environmental footprint due to the mining and processing involved. In contrast, mtrl.bike uses recycled plastics, which help reduce waste and the demand for new plastic production.

By using recycled materials, mtrl.bike contributes to the reduction of plastic waste—a significant environmental threat. Furthermore, the use of renewable energy in the manufacturing process ensures that the production is cleaner, aiming to reduce traditional energy consumption and greenhouse gas emissions associated with manufacturing.

More To Discover

This model of using recycled plastics and renewable energy not only illustrates a commitment to environmental sustainability but also sets a precedent for other companies in the industry to follow. It showcases a tangible solution to the global issue of plastic waste, positioning recycled plastic bicycles not just as a product but as a statement in the movement towards a more sustainable future.

mtrl.bike offers more than just a new kind of bicycle; it presents a vision for a sustainable model in product design and manufacturing that could inspire broader changes in how products are made and used globally. As we continue to confront the challenges of plastic waste and climate change, initiatives like mtrl.bike demonstrate the potential for innovative approaches to make a real difference.