Shinkei is working to make the seafood on your plate not only tastier, but also ethically harvested. This Japanese company is pioneering a technology that could transform the seafood industry by making the process of harvesting fish far more humane and quality-preserving.

If you’re expecting to read a paid post disclaimer, there isn’t one. Dakoa isn’t being compensated for this post. Our mission is to put a spotlight on the good and bad of environmental issues, companies, greenwashing, etc. Shinkei is doing good things, and we want you to know about it. Any company that’s trying to make a practical, sustainable difference is compensation enough.

The Problem with Current Practices

At present, the process of harvesting fish is grueling and inefficient. Fish typically suffocate on the decks of ships, thrashing violently until they die. This not only causes the fish undue suffering but also degrades the quality of the meat due to injuries and bacterial infections, leading to a shorter shelf life and a compromised taste. And it’s flat-out mean.

Enter Ike-jime: An Ancient Method Reimagined

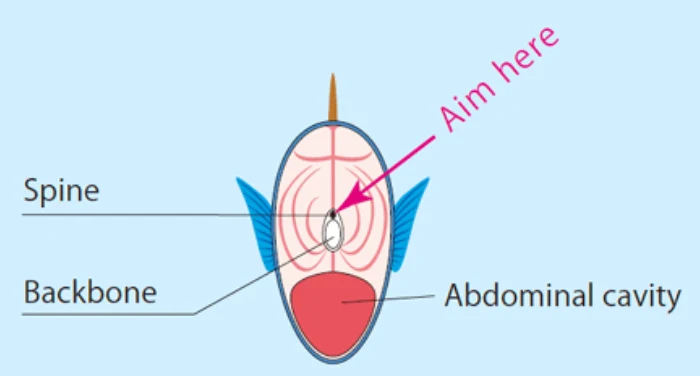

Ike-jime, a traditional Japanese method that involves a swift spike to the brain, presents a humane alternative to the chaotic death many fish currently endure. This method, while effective, requires skill and can only be applied to a limited number of fish by hand. Shinkei’s innovative technology automates this technique, allowing for quick, precise execution without the need for extensive manpower.

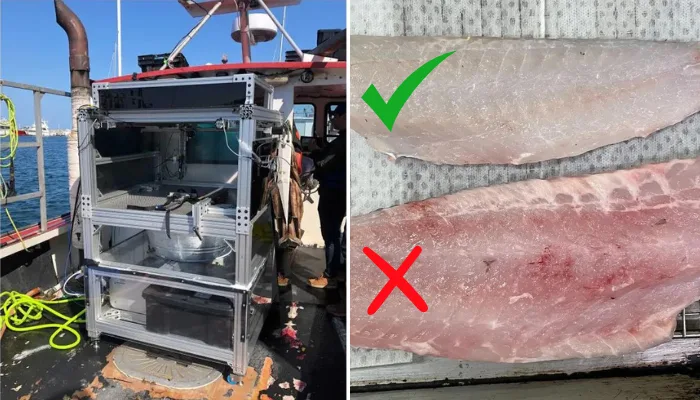

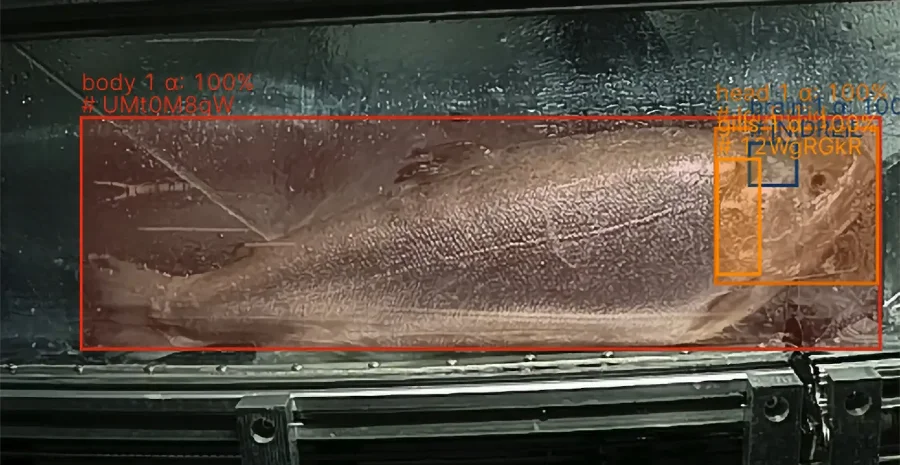

The company was deploying its first prototypes onto vessels in 2022 to be tested in the unpredictable marine environment. The machine holds the fish in place, identifies the species and shape, and from there can determine where exactly the brain is, which it spikes quickly and accurately. For the fish, it receives a painless and quick death and consumers receive a higher-quality product.

Technological Advancements and Expansion

Since the initial testing phase, Shinkei has significantly advanced its technology. Founder Saif Khawaja shared that the company has transitioned from a water-based spike to a more reliable mechanical one. “We’ve refined our machines to be more reliable,” Khawaja notes, highlighting the evolution from prototype to production units.

The systems are now modular, allowing multiple machines to operate concurrently, which enhances the processing speed. Moreover, the technology’s computer vision stack, which analyzes and identifies the fish, is continuously being upgraded to include new species.

Economic and Environmental Implications

Khawaja believes that the adoption of Shinkei’s technology could signal a major shift in the seafood economy, like past revolutions in other agricultural sectors. He draws parallels to the 1970s, when humane slaughter practices for cattle were mandated, leading to widespread changes in the industry.

Fish processed through ike-jime retain their premium quality longer, potentially reducing the quantity of fish restaurants need to purchase and discard. “That means a restaurant may not have to buy as many fish, a quarter of which it will throw away perhaps, but will pay more for fewer higher-quality fish that last longer,” Khawaja explains.

This shift could recalibrate the entire seafood supply chain, increasing the value of locally processed fish and reducing the need for overseas processing.

The Fight Against Overfishing

Furthermore, higher-quality, longer-lasting fish could also help combat overfishing—a significant problem in global fisheries. “Higher-value fish may also put negative pressure on overfishing,” Khawaja asserts. “If a boat can make the same amount of money on 700 fish as it once did on 1,000, that changes things as well.”

Vision for the Future

More To Discover

- Panasonic’s Innovative Semi-Transparent Perovskite Solar Panels Look Like Windows or Walls

- 9 Trailblazers of Mycelium-Based Meats: 8 Young Fungi Brands You Can Eat Right Now And Their Godfather

- Climate Change Rolls Back Decades of Clean Air Progress in U.S., Study Reveals

- MIT Paves Way for Next-Gen Solar With Guide On Commercializing High-Energy Perovskite Cells

With a recent $6 million funding round led by Cantos and supported by multiple investors, Shinkei is poised to expand from pilot to full production. Khawaja’s vision extends beyond automation; he sees an opportunity to make the seafood supply chain safer and more efficient, thereby preserving not just the fish but also the jobs of those who work in this perilous industry.

As Shinkei gears up to deploy its innovative machines more widely, the potential benefits ripple through economic, environmental, and ethical dimensions, promising a future where the seafood industry is as sustainable as it is humane.