In an era where plastic pollution poses a colossal threat to our planet, a groundbreaking discovery has emerged from the labs of King’s College, London. Scientists there have cracked the code to a problem that’s been plaguing the world: efficiently recycling single-use bioplastics. Their solution? An enzyme, commonly found in biological laundry detergents, can recycle these stubborn materials within a mere 24 hours.

A Leap Forward in Bioplastic Recycling

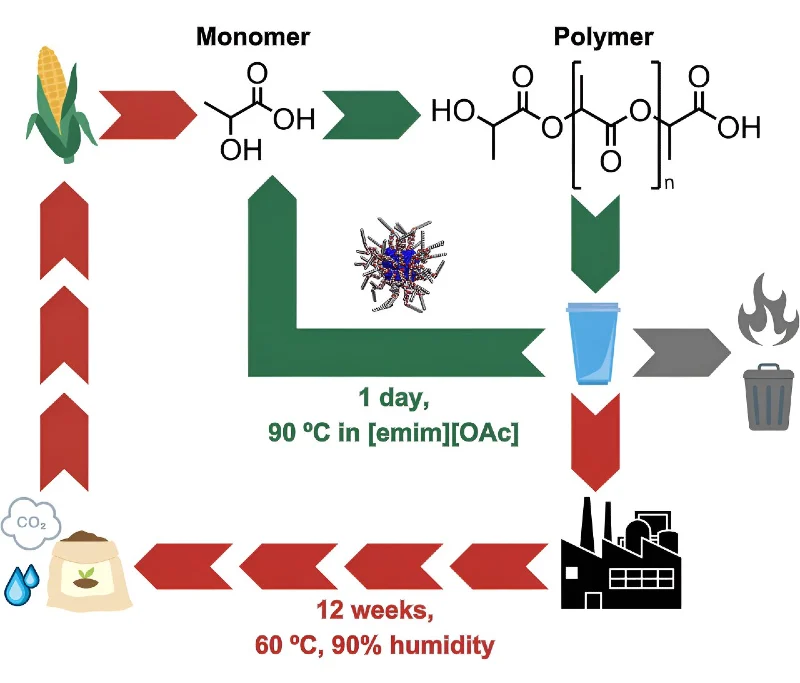

Published in the journal Cell Reports Physical Science, this method of chemical recycling utilizes enzymes to depolymerize, or break down, bioplastics that are destined for landfills. This remarkable process rapidly converts items like disposable coffee cups and food containers into soluble fragments, achieving full degradation of the bioplastic polylactic acid (PLA) in just one day.

This speed is a game-changer, outpacing the traditional 12-week-long industrial composting process by a staggering 84 times.

The King’s College chemists didn’t stop there. They discovered that within an additional 24 hours at 90°C, these bioplastics break down further into their chemical building blocks, the monomers. These can then be repurposed into high-quality plastic for multiple reuses, opening the door to a sustainable loop of plastic use and reuse.

Tackling the ‘Green’ Plastic Dilemma

The urgency of this development cannot be overstated. A report by Environmental Action highlights the alarming fact that, in 2023 alone, over 68 million tons of plastic ended up in natural environments worldwide.

This crisis is exacerbated by the production of bioplastics—often lauded as a sustainable alternative to traditional plastics. Derived from biological sources like corn starch and sugarcane, bioplastics have been seen as the eco-friendly choice.

However, their production is costly, competes with food agriculture, and the end product often ends up in landfills due to inefficient recycling methods.

Dr. Alex Brogan, a leading chemist at King’s College, shared the inspiration behind their research, “The inspiration for this project came from a problem with bioplastics used in medical and surgical products degrading in the body. We’ve turned this problem around and applied it to the issue of recycling the single-use bioplastics we use in our everyday lives using a common enzyme found in biological laundry detergent.

Being able to harness biology to deliver sustainable solutions through chemistry allows us to start thinking of waste as a resource so that we can move away from oil and other non-renewable sources to create the materials we need for modern life.”

Beyond Bioplastics: A Future of Sustainable Solutions

This discovery isn’t just a triumph in recycling bioplastics; it’s a beacon of hope for the future of plastic management. The team at King’s College is already expanding their research to include other commonly used plastics, such as those in water bottles and packaging.

Susana Meza Huaman, a Ph.D. researcher on the project, emphasized the significance of their work, “Our research marks the first step in developing new technologies in waste management for recycling bioplastics that are of equal quality to the virgin product.

Until now this has been a major challenge in plastics recycling, as while bioplastics are made of biological materials, they are not all compostable and most current recycling methods are inefficient. Our chemical approach significantly speeds up the degradation of bioplastics, enabling them to be recycled and reused.”

More To Discover

- How Cutting-Edge Robotics and Smart Hives Just Might Save Our Honeybees

- Behind The Scenes Of How Tyson, JBS, Cargill, and National Beef Use Consolidation And Auctions To Control The Beef Industry

- Collected Challenges in the Renewables Industry: The Green Energy Sector Has Had Some Bad Days

- UK’s Chicken Industry in Crisis: 80 Million Deaths Point to Unsustainable Practices

This breakthrough from King’s College London is more than a scientific achievement; it’s a clarion call for a sustainable, circular economy.

It’s a path forward to tackle the daunting challenge of plastic waste, steering us away from fossil-based plastics, and reimagining waste as a valuable resource. With this enzyme, we’re not just recycling plastic; we’re recycling hope for our planet’s future.