Imagine a world where waste isn’t just discarded, but transformed into something valuable. In India, where 500 million tonnes of crop residue are produced annually, much of it is burned, releasing a staggering 150 million tonnes of carbon dioxide into the atmosphere. This practice contributes significantly to air pollution and climate change. Craste, an innovative company, saw an opportunity in this problem. They decided to use this abundant crop waste to create a sustainable alternative to traditional packaging.

Craste, the brainchild of a dedicated team in India, has pioneered the country’s first 100% tree-free packaging solution. Their approach is both simple and revolutionary: collect crop residue from farmers and convert it into high-quality packaging materials. The heart of this process is their patented circular fiber technology, which transforms crop waste into tree-free pulp. This method is remarkably eco-friendly, requiring less water and producing zero waste discharge.

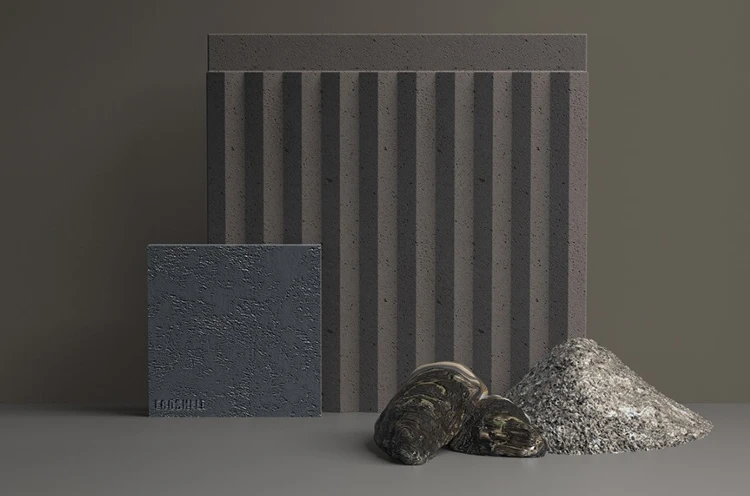

The pulp produced through this process is versatile and can be turned into various packaging products, including boxes, paper bags, and envelopes. Notably, the packaging is food-grade, ensuring it’s safe for food products. The material is also robust yet flexible, capable of maintaining its shape and form, making it a practical choice for numerous applications.

Craste’s vision extends beyond just packaging. They’re developing durable, environmentally friendly, cost-effective, wood-equivalent crop residue-derived straw panel boards. These boards are bonded with a formaldehyde-free adhesive, further reducing their environmental impact.

One of the biggest challenges facing eco-friendly packaging solutions is cost. Traditional materials like single-use plastics and bubble wrap are cheap, making them attractive to businesses. However, Craste’s innovative approach offers a promising alternative that could change the packaging industry.

As more companies adopt sustainable practices, the demand for green packaging solutions will grow, potentially lowering costs over time.

How Craste’s Product is More Sustainable

First, by using crop residue, they reduce the need to harvest trees, conserve forests and increase biodiversity. This also helps manage agricultural waste, preventing it from being burned and releasing harmful pollutants into the air.

The circular fiber technology employed by Craste is designed to be highly efficient. It consumes less water compared to traditional pulping processes and ensures zero waste discharge, making the entire operation more sustainable. Additionally, the packaging materials produced are biodegradable and recyclable, contributing to a reduction in overall waste.

This eco-friendly alternative to traditional packaging reduces carbon emissions and promotes sustainable agricultural practices. Both are great for the environment, making Craste’s product line and vision highly sustainable, but there’s a financial incentive for the farmers as well. Craste gives value to what was once considered waste, creating a new revenue stream for the farmers.

More To Discover

- Sun-Chasing Streetlights: Solar Lamps Spin and Move to Brighten Our Streets

- SEAD’s Sustainable Seed Pods from Seafood Waste For Eco-Friendly Gardening

- Why You Should Ditch Laundry Pods and Embrace Sustainable Alternatives

- Cryptocurrency and the Environment: In-Depth Study Examines The Hidden Costs of a Digital Gold Rush

Craste’s innovations are an essential step towards a more sustainable future.

As they continue to develop and refine their products, the hope is that eco-friendly packaging will become more accessible and affordable, encouraging widespread adoption and a shift towards greener practices in the packaging industry.