Engineered stone, also known as artificial or composite stone, has gained immense popularity in the construction and design sectors for its aesthetic appeal and durability. Particularly in modern kitchens and bathrooms, engineered stone has become the preferred choice for countertops and benchtops. Yet, beneath its attractive surface lies a hidden danger, one that poses significant health risks to the workers involved in its manufacturing and installation.

The hazards associated with engineered stone have remained unnoticed for too long, but now the call for action is growing louder worldwide. Let’s delve into the reasons behind the harm caused by engineered stone and explore the global efforts to mitigate its risks, all while considering its impact on sustainability.

The Hazards

Engineered stone used for countertops is primarily composed of quartz, one of the hardest minerals on Earth. The manufacturing process involves grinding quartz into dust and combining it with resins and pigments to create a product that replicates the beauty of natural stone. Natural stone in large, uniform, aesthetically-perfect pieces suitable for countertops is scarce and expensive. Engineered stone countertops offer a cost-effective alternative as they can be fabricated to any size or shape while providing enhanced durability and stain resistance due to their non-porous nature. Many engineered stone countertop products contain a high silica content, often up to 95%, making them a popular choice for kitchens and bathrooms.

The real danger of engineered stone lies not in its installed form but in the dust generated during the cutting, grinding, and polishing processes, typically occurring during manufacturing or installation. This dust contains high levels of crystalline silica, which, when inhaled, can penetrate deep into the lungs. Silica dust exposure can lead to silicosis, a debilitating and often fatal lung disease. The dust particles settle in the alveolar sacs of the lungs, causing irreversible damage.

Over time, macrophages, immune system cells responsible for pathogen destruction, ingest the dust particles, triggering collagen production around them. This process results in fibrotic nodules in the lungs, inhibiting lung function and causing symptoms such as shortness of breath, rapid breathing, persistent coughs, and fatigue. Patients with silicosis are also at a higher risk of tuberculosis infection, lung cancer, and chronic obstructive pulmonary disease (COPD).

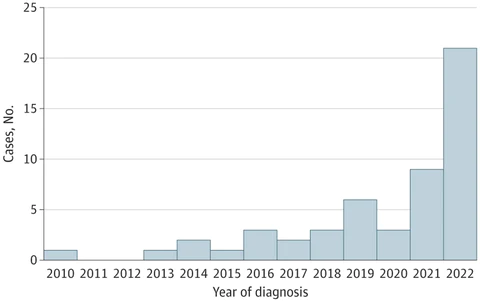

The surge in the use of engineered stone has corresponded with a troubling increase in silicosis cases, especially among young workers in the stone cutting industry. Many of these workers have developed advanced stages of the disease after only a few years of exposure, leading some to dub engineered stone as “the new asbestos.”

Australia Takes Action

In Australia, the first case of silicosis linked to engineered stone was identified in 2015, followed by 570 more cases. Unlike some traditional industrial hazards that take decades to manifest, silicosis from engineered stone was striking down workers in their prime, with many under the age of 35.

This alarming rise in cases triggered a nationwide outcry for action. In October of this year, the Construction, Forestry, Mining, and Energy Union (CFMEU) voted in favor of a ban on engineered stone. The broader union movement in Australia also supported the ban, ensuring that no union workers would allow the importation, manufacturing, or use of the material in the country from mid-2024. Major hardware retailers committed to phasing out the material by the end of the year, and furniture giant Ikea also pledged to remove it from its kitchen range.

Australian authorities responded with a groundbreaking prohibition on engineered stone, set to commence on July 1, 2024. The measures include customs restrictions on importing the material and a complete ban on its manufacturing, supply, processing, or installation.

Government reports highlighted that there was “no scientific evidence for a safe threshold of crystalline silica content in engineered stone” and that lower silica content variants did not guarantee safety. Even personal protective equipment was found to be insufficient in reducing the risk of harm.

Prior to the ban’s implementation, Australian authorities mandated safer working procedures. These procedures include water suppression “wet cutting” systems or the use of dust extraction and ventilation systems. Workers are also required to use appropriate respiratory protective equipment.

These actions taken by Australia serve as a model for other countries grappling with similar issues. The ban on engineered stone underscores the seriousness of the health risks associated with silica dust exposure and highlights the need for a global reassessment of materials that endanger workers’ health.

More To Discover

- Puzzle-Inspired Electric Minivan: Where Modular Design Meets Sustainability – Ugly Yet Promising

- Transforming Palm Trees into Eco-Friendly Building Materials: A Green Innovation to Tackle Construction Emissions

- Panasonic’s Innovative Semi-Transparent Perovskite Solar Panels Look Like Windows or Walls

- Fin-Driven Motor: FinX Introduces Propeller-Free Boating

The Global Impact on Sustainability

The ban on engineered stone in Australia not only prioritizes worker safety but also has a significant impact on sustainability. While engineered stone offers desirable qualities like durability and aesthetic appeal, the health risks it poses can’t be ignored. The ban highlights the importance of vigilant regulation and a commitment to worker safety in industries worldwide.

Beyond that, it encourages a reconsideration of materials with potential health hazards and prompts industries to prioritize the health and well-being of those who contribute to the production of these products. In the pursuit of sustainability, it’s essential to ensure the safety and welfare of workers, aligning environmental and human well-being goals. As we move forward, Australia’s bold move should inspire other nations to take similar measures to protect their workers and promote sustainable practices in the construction and design industries.