Giving Date Seeds a Second Life in Sustainable 3D Printing

The rise of 3D printing has been transformative, but it’s not without its drawbacks. The widespread use of plastic filaments, even biodegradable options like PLA, contributes to waste and environmental concerns.

Designer Nawa Tec created RePit to solve two problems at once: the overuse of plastic in 3D printing and the mountains of food waste created by discarded date seeds.

Transforming Food Waste into Filaments

Dates are a dietary staple in countries like Oman, where tons of the fruit are processed yearly. The pits, or seeds, are typically discarded, adding to waste piles despite being biodegradable. Without intervention, these seeds often occupy landfills or contribute to water pollution.

In 2022, the global date palm industry produced at least 975,000 kgs of date seeds (that’s over 10 million tons), most of which is considered waste. RePit turns these useless date pits into 3D printing filaments.

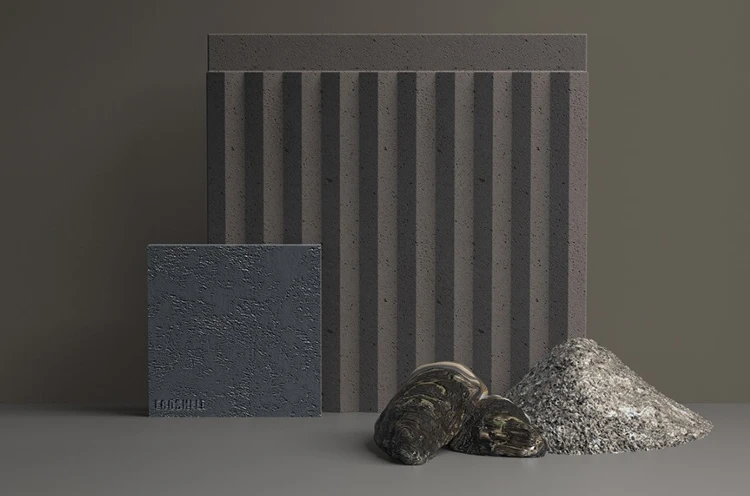

The waste seeds are crushed and combined with limestone and clay to create a durable composite material.

This material is water-resistant, like the traditional Iranian sarooj, used for construction for centuries. The result? A filament that’s eco-friendly, functional, and compatible with FDM 3D printers.

More To Discover

"Usually, the seeds are just left lying about, but we wanted to create another life for them."

Umayma Al Hinai, Nawa architectural engineer

Practical Applications

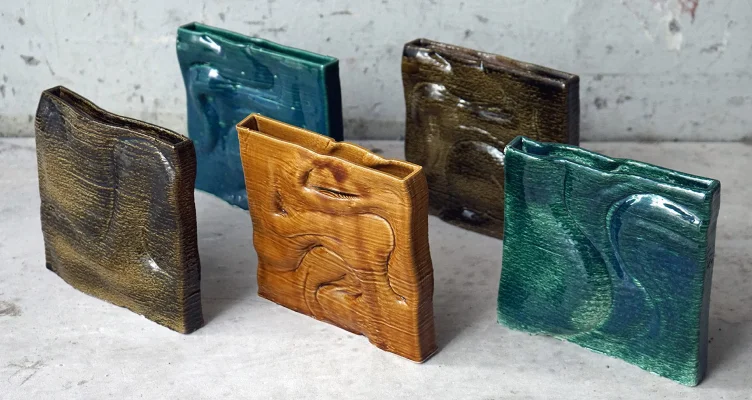

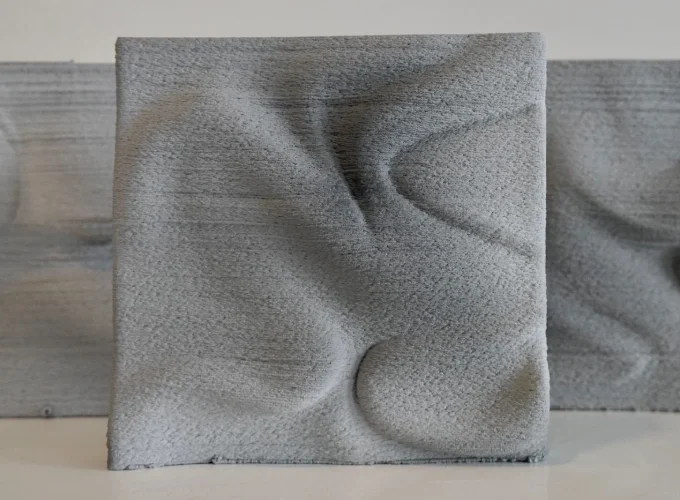

RePit’s demonstration project showcased its potential by creating decorative tiles using the date seed filament.

The tiles were 3D printed, fired, and glazed to achieve a ceramic-like finish, highlighting the versatility of the material.

While still in development, the concept promises endless applications, from functional machine parts to intricate art objects, all while reducing waste.

Why It Matters

3D printing is often praised for reducing manufacturing waste, but it still relies heavily on thermoplastics derived from petroleum.

Even PLA, a plant-based alternative, has limitations—it’s only biodegradable under specific industrial conditions, which most environments lack.

RePit is substituting plastic with date seed composites to reduce emissions and lower the carbon footprint and divert waste from landfills, all while supporting a localized circular economy. The company is sourcing their initial date waste from local farms around Oman.

The farmers are making some money off what was, traditionally, worthless. All of that date waste is now transformed into a viable resource, reducing reliance on virgin materials while tackling the broader issue of food waste.

Globally, food waste contributes to significant greenhouse gas emissions, with discarded seeds making up a substantial part of the problem.

The Bigger Picture

RePit is part of a broader movement toward sustainable 3D printing materials, joining efforts to integrate wood, metal, and even food-based materials into production.

While still a work in progress, innovations like this pave the way for a greener future in manufacturing and design.

By repurposing local waste into practical materials, RePit demonstrates how eco-conscious thinking can spark groundbreaking ideas. If scaled, it could transform the way we approach both food waste and 3D printing’s environmental footprint.

Nawa is an all-female collective of designers, architects, chemical engineers, and bio-scientists based in Oman. The firm is committed to producing environmentally conscious and sustainable products.

Watch the 2-minute video below to get to know the amazing team behind Nawa (it’s in English).