Fashion has always been a mirror, reflecting societal shifts and cultural transformations. Today, it mirrors our deepening concern for the environment as sustainability in the fashion industry has gone from a marketing buzzword that consumers pretend to care about, to a buying decision. Today we’re going to examine polylactic acid (PLA).

The Roots of PLA in Fashion

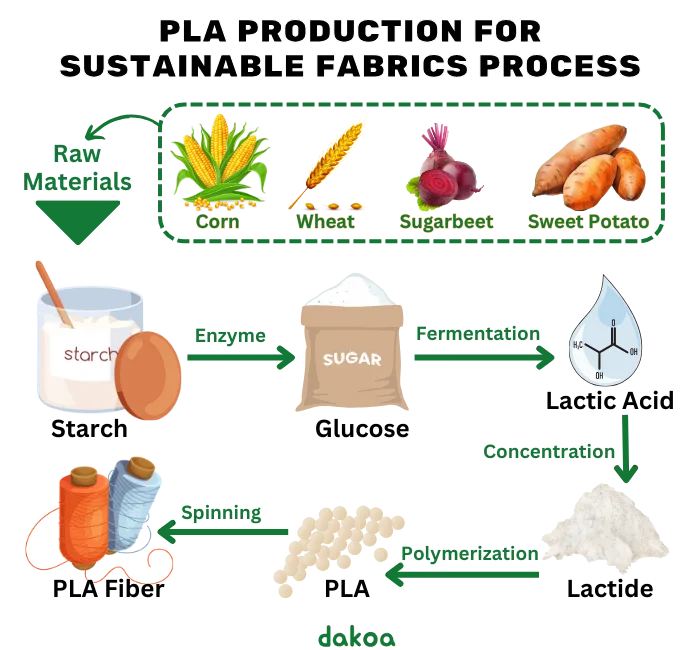

PLA is derived from corn starch. As the fashion industry grapples with its environmental impact—responsible for a staggering 10% of global carbon emissions—PLA offers a promising alternative. Not just because it’s biodegradable, but also for its minimal ecological footprint during production. And this point can’t be highlighted enough.

Why PLA?

The appeal of PLA is multifaceted. For starters, it biodegrades within a year if buried in the right conditions. Compare this to polyester, a petroleum byproduct, which can take centuries to break down.

PLA’s production also emits significantly fewer greenhouse gases. And as far as durability and resilience goes, PLA provides both (similarly to cotton) making it practical for long-term everyday wear.

Production of PLA

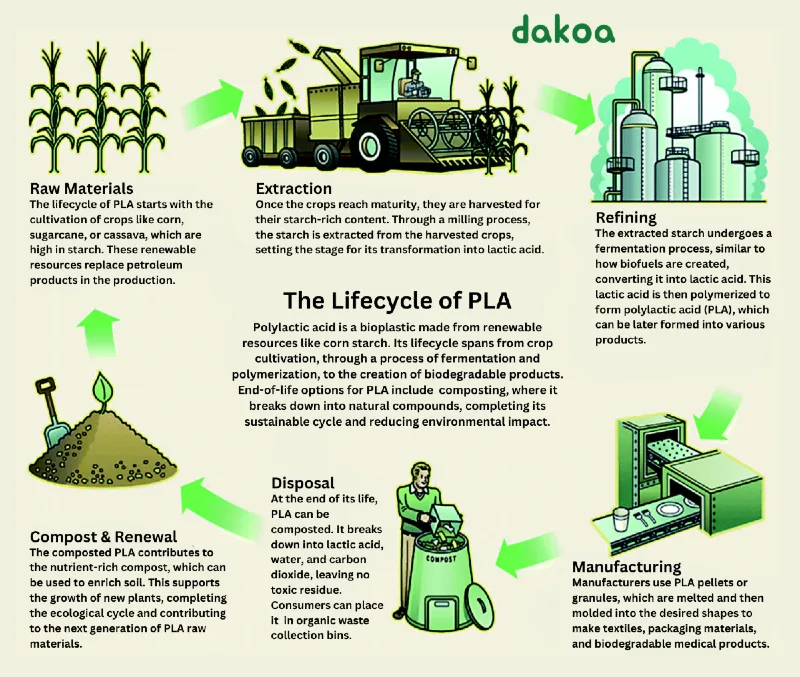

PLA is produced from renewable starchy resources like corn starch or sugar cane, making it a sustainable alternative to traditional petrochemical plastics. The process involves fermenting plant starch into sugar, which is then transformed into lactic acid. This lactic acid is polymerized to create PLA, which, by definition, has become a type of polyester. This production process uses 65% less energy than traditional plastics and generates 68% fewer greenhouse gases.

All wins in the sustainability column for sure.

Eco Credentials

The environmental credentials of PLA are better than bamboo and any oil-based material. We’re talking lower carbon emissions and fewer chemicals required throughout the production process. All that makes a difference. Of course, PLA is also fully biodegradable and can degrade into harmless lactic acid under the right conditions, which sounds sneaky but what that really means is simple.

Toss a PLA shirt into your compost bin, and it’ll break down within a few months, if using the hot composting method, or around a year with the cold composting method. Either way, PLA has a much smaller ecological footprint compared to non-biodegradable plastics (and most plastics are nonbiodegradable).

Patagonia’s Stance on PLA

After reading everything about PLA, you may recall that one of the most successful eco-friendly brands has stated that they won’t use the material in their clothing. Here’s Patagonia’s stance on the matter from their website:

“It’s made from corn and much of the corn currently available for this application is genetically engineered and because we as a company are against the use of genetically engineered crops, we can hardly use it for clothing. Using corn also puts us at the mercy of corn as a commodity; its wild price swings in the past two years as a result of the rush to develop ethanol technology are an example of something we’d just as soon steer clear of. Lastly, while PLA is technically biodegradable, it’s not yet available in a form that will disintegrate in that compost pile in your backyard; currently, it is compostable only on an industrial scale.”

This was the company’s stance in 2009 and hasn’t been updated since but is still readily available on their website. Let’s go over their points one by one:

- Most corn is genetically engineered, which is why it’s able to grow around the world in harsh conditions and feed hundreds of millions of starving people. Patagonia opposed genetically modified organisms (GMOs) in 2009 and hasn’t updated their viewpoint, even with a great deal of science that no longer supports their opinion.

- Corn is a commodity, so the pricing does go up and down regularly and often unpredictably. Avoiding corn for this reason is a wise business decision by any clothing retailer.

- In 2009 PLA could only be composted using an expensive industrial method. Much has changed in 15 years, and now the material can be composted in your backyard compost bin.

Challenges For PLA In Fashion: So Where Can I Buy PLA Clothes?

PLA faces four distinct hurdles to showing up in your local Walmart. I would have written department store, but most of them are shutting down these days.

Before you go searching for brands that feature PLA on Amazon, or (and please don’t do this) Shein, you should know that it’s far from a mainstream material. And the main reason why is simple – it’s expensive. Right now, PLA is more expensive to produce on a large scale than any traditional fibers. But the technology to process PLA at scale is progressing because demand for sustainable products are increasing, so these costs will decrease.

Another big hurdle lies in consumer behavior itself. Switching to sustainable materials requires not just availability, but also a willingness from consumers to adapt. It’s very easy for shoppers to say they’re willing to spend 20% more on an eco-friendly shirt, but statistically speaking they hop on Shein, buy 10 shirts for $4 each from China and lie about it.

The third issue surrounding PLA as a mainstay fabric carries a touch of practicality – low heat resistance. PLA’s low glass transition temperature makes it unsuitable for items requiring high thermal stability, like garments that need to withstand high washing temperatures.

And finally, the practical production problem. Processing PLA can be challenging because it’s different from traditional plastics, meaning facilities must make large investments in new equipment and processes. This hits the efficiency of manufacturing processes in the fashion industry, where both high-speed production and cost are top priorities.

What Shouldn’t Be Made With PLA?

And we’re back to the garments that need to withstand high washing temperatures, which commonly include those that are heavily soiled, used in environments where sterilization is important, or made from materials that can handle heat without deteriorating.

Need some examples? Got you covered! Here are some common types of garments and uses that require high washing temperatures:

- Workwear and Uniforms: Clothing used in professions like healthcare, culinary, and mechanical fields require frequent high temperature washing to remove stains, bacteria, and oils. For example, chefs’ jackets and mechanics’ overalls are typically covered in grease and food stains and those are best removed with regular washing at high temperatures.

- Hospital Linens and Scrubs: In medical settings, scrubs, sheets, and other linens need to be washed at high temperatures to ensure they’re free from pathogens and other contaminants. And one doesn’t want to shortcut this! We all want to maintain hygiene and prevent the spread of infections within healthcare facilities.

- Sports and Athletic Wear: Athletic wear, such as gym clothes and team uniforms and jockstraps, require washing at higher temperatures to effectively remove sweat, dirt, and odors. Without proper cleaning, these garments can harbor bacteria and fungi and that’s not pleasant!

- Towels and Bedding: Towels, bed linens, and other similar items are typically washed at higher temperatures to kill bacteria and dust mites and remove body oils and other residues. All pretty important facets of maintaining good household hygiene.

- Children’s Clothing and Cloth Diapers: Baby clothes and reusable cloth diapers often need high temperature washing to ensure they are spotless and sanitized, especially since infants have sensitive skin and are more vulnerable to infections.

- Pet Bedding: Items used by pets, such as dog or cat beds, are washed at high temperatures to eliminate pet odors, fur, and to kill fleas or ticks.

Garments made from durable materials like cotton and certain polyesters can withstand these higher temperatures without any noticeable degradation. Unfortunately, garments made from more delicate or temperature-sensitive materials, like PLA-based fabrics, aren’t suitable for high-temperature washing.

But look at this ‘limitation’ of PLA from a different perspective. The material’s inability to withstand regularly high-temperature washings is also one of the reasons why it decomposes so quickly compared to cotton or other fibers. Simply put, if you want sustainable fabric that decomposes fast AND can hold up to many high-temperature washings, well, you’ll have to become a sorcerer and magic one into existence.

Is PLA Being Used Now?

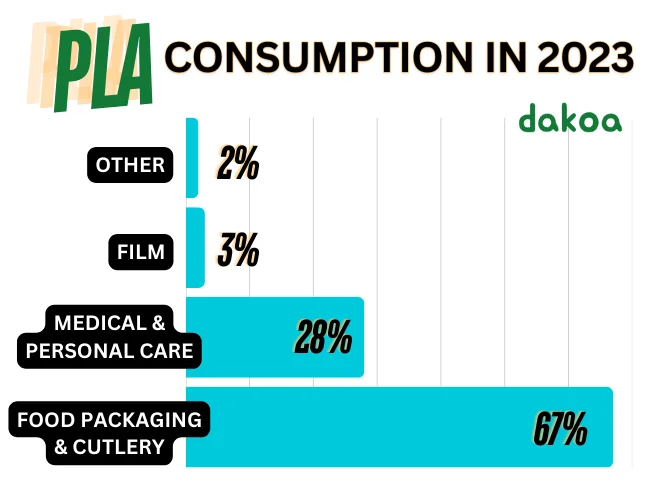

While textile manufacturers haven’t jumped on the PLA train just yet, the substance is currently used in biodegradable medical devices and eco-friendly packaging solutions.

Biodegradable Medical Devices

More To Discover

- Sustainable Circuit Boards That Turn to ‘Jelly’ for Effortless Recycling

- mtrl.bike Eco-Friendly Bicycles with Recycled Plastics and Renewable Energy

- Puzzle-Inspired Electric Minivan: Where Modular Design Meets Sustainability – Ugly Yet Promising

- Sustainable Bottle Cap Alerts You to Food Freshness, Reducing Waste and Possible Illness

- Surgical Implants: Includes pins, screws, and plates that naturally dissolve in the body over time, eliminating the need for a second surgery to remove them.

- Orthopedic Devices: Used in bone fracture repairs and orthopedic surgeries to support bones and joints as they heal.

- Dental Implants: PLA is used in the manufacturing of temporary crowns, bridges, and orthodontic devices that biodegrade over time.

- Drug Delivery Systems: PLA-based capsules and implants that gradually dissolve to release medications over a controlled period.

Eco-friendly Packaging

- Food Packaging: PLA is used for creating compostable containers, cups, and films that are used to package fresh produce, bakery items, and ready-to-eat meals.

- Disposable Tableware: Includes biodegradable plates, cutlery, and straws, ideal for reducing waste in fast-food and takeaway industries.

- Agricultural Films: Biodegradable mulch films made from PLA help improve crop yield while reducing the environmental impact compared to traditional plastic films.

- Loose Fill Packaging: Used as biodegradable packing peanuts and air pillows for shipping and handling, offering a sustainable alternative to styrofoam and other synthetics.

The future of PLA in sustainable fashion looks promising as technological advancements continue to reduce production costs and enhance the material’s properties. With rising oil prices and increasing environmental awareness, PLA is starting to get some attention again as a financially viable and eco-friendly material.