In a world constantly searching for sustainable solutions, Lea Lorenz, an industrial designer, introduces Tony – a groundbreaking electricity-free refrigerator. This portable food container is a nod to the past, reinventing the way clay pots were used for storing fruits and vegetables for over a millennium. Tony isn’t just a fridge; it’s a blend of traditional wisdom and modern innovation, harnessing evaporative cooling to keep perishables fresh without harming the environment.

Calling it a refrigerator may be a bit much, but it doesn’t buzz or hike up your electricity bill, so that’s a nice change.

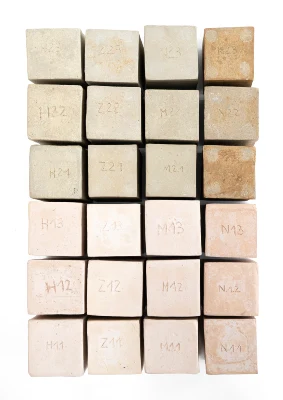

At its core is a porous raku clay shell. The clay itself is special. It absorbs water from a built-in reservoir, and as the water evaporates, the magic happens. The temperature inside drops to a cozy 13°C-17°C (55°F-62°F), perfect for most fruits and veggies.

You know how sometimes fruits lose their taste in the fridge? Tony takes care of that. Lea Lorenz puts it best, “This temperature range creates an ideal storage environment for foods that are sensitive to extreme cold.”

But getting Tony just right wasn’t easy. Lea experimented with various clays and mixtures, and the winner was Raku clay. Its superpower? Absorbing water like a champ.

Tony’s design is simple yet effective: a water tank, a food container, and a lid. Each part does its job independently, working together to keep your food fresh. The outer wall of Tony is designed to increase surface area, making water evaporate faster and cooling your food quicker. It’s the same general concept used in evaporative cooling systems throughout the world to cool buildings in hot, arid climates without air conditioning.

Lea’s design includes a simple, study wooden stand for easy mobility. Sure, it looks nice, but the mobility is important because sunlight and heat can affect Tony’s performance. This could be considered a drawback to the product design because you can’t automatically place Tony wherever you’d like in your kitchen. In fact, the coolest area may not be in your kitchen at all.

The product was designed to accommodate different fruits and vegetables. It’s stackable and allows separation between items, when necessary, which helps reduce food spoilage.

Now, let’s talk sustainability.

The Raku clay comes from the Westerwald region in Germany, keeping transport short and CO2 emissions low. Even the production process is eco-friendly, with the clay being fired at just 1000°C to save energy. And if Tony ever breaks down, no worries – the clay can be recycled into fireclay to make new coolers, affording a cyclical lifecycle.

So, what makes Tony more sustainable than your average fridge?

For starters, it runs without electricity. That means zero energy consumption, zero emissions, and a much smaller carbon footprint. Its materials are locally sourced and recyclable, making it a friend to the planet. But it’s not just about being green; it’s about efficiency. By maintaining optimal temperatures for specific produce, Tony reduces food waste. Less spoilage means less food thrown away, and that’s good for the environment.

However, Tony isn’t without its challenges.

Its performance can be affected by external temperatures and humidity (which we already covered), making it less effective in some climates. And while the clay is sustainable, the question remains whether its manufacturing process, including firing at high temperatures, is entirely eco-friendly. After all, we’re not sure what’s powering that 1,000 degree kiln.

Although we can be certain of one thing, manufacturing clay segments for Tony is inherently better than manufacturing a large refrigerator. And while this product won’t eliminate the need for expensive fridges or dramatically lower our electricity usage, it can make a small difference by reducing the overall size of our refrigeration needs. It can also improve how many people in developing countries live by affording them access to refrigeration.

Tony might not be perfect, but it’s a step in the right direction.

Meet The Designer: Lea Lorenz

“In my role as a designer, I question the manufacturing process, the choice of materials and the functionality in the design of objects that we use in our daily lives. I develop new approaches and solutions scientifically and experimentally. I solve problems as simply and functionally as possible, and always see it as a central part of my work to use the finite resources of our planet as efficiently as possible.”

Lea Lorenz, German Industrial Designer