Three decades ago, in Germany, a visionary botanist named Siegfried Fink harbored a simple yet profound desire: to unveil the inner mysteries of woody plants without resorting to dissection. Through a meticulous process of pigment removal from plant cells, Fink achieved the impossible—transparent wood. His groundbreaking technique was documented in a niche wood technology journal back in 1992, a publication that remained the solitary reference on see-through wood for over a decade, until a fortuitous discovery by a researcher named Lars Berglund.

While Fink’s motivation was purely botanical, Berglund, a materials scientist at Sweden’s KTH Royal Institute of Technology, saw the potential of transparent wood from an entirely different perspective. His expertise lay in polymer composites, and he envisioned a robust alternative to transparent plastics.

Unbeknownst to Berglund, across the ocean, researchers at the University of Maryland shared his fascination with wood’s untapped potential, seeking to harness its strength for unconventional applications.

After years of dedicated experimentation, the collective efforts of these research groups are now bearing fruit. Transparent wood stands on the precipice of revolutionizing multiple industries, serving as the backbone for super-strong smartphone screens, soft and luminous light fixtures, and even innovative structural elements like color-changing windows.

“I firmly believe that this material holds great promise,” asserts Qiliang Fu, a wood nanotechnologist from Nanjing Forestry University, who once worked in Berglund’s laboratory as a graduate student.

Wood comprises countless vertical channels, akin to a tightly bundled collection of straws, held together with adhesive glue. These tube-shaped cells play the role of transporting water and nutrients throughout a tree. When a tree is harvested and moisture evaporates, it leaves behind pockets of air.

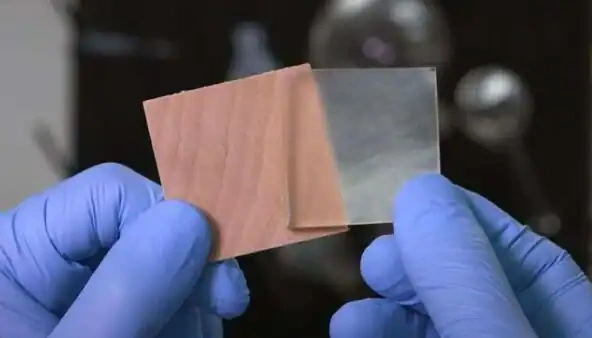

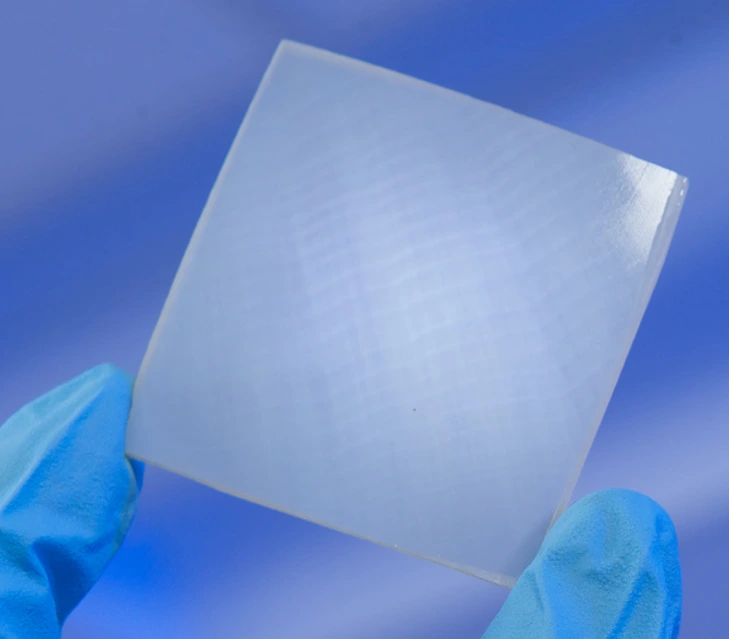

To transform wood into a transparent wonder, scientists must first alter or eliminate the glue, known as lignin, which not only binds the cell bundles but also imparts the earthy brown hues to trunks and branches. After successfully bleaching away lignin’s color or eliminating it by other means, what remains is a milky-white skeleton of hollow cells.

However, this skeletal structure remains opaque because the cell walls refract light differently from the air within the cell pockets, creating a disparity in refractive index. To achieve transparency, the air pockets need to be filled with a substance like epoxy resin that bends light in a manner similar to the cell walls.

The material scientists have worked with is typically thin, ranging from less than a millimeter to around a centimeter in thickness. Yet, despite its slender profile, the honeycomb-like structure of the cells and the remarkable strength of the tiny wood fibers make it stronger than even the finest carbon fibers.

Leading the charge in transparent wood research, materials scientist Liangbing Hu of the University of Maryland in College Park notes that with the addition of resin, transparent wood surpasses both plastic and glass.

In tests assessing materials’ fracture resistance and pressure tolerance, transparent wood emerged as roughly three times stronger than transparent plastics like Plexiglass and approximately ten times tougher than glass.

“The results are astounding, demonstrating that a piece of wood can rival glass in strength,” declares Hu, who showcased the exceptional qualities of transparent wood in the 2023 Annual Review of Materials Research.

While this process also functions with thicker wood, the view through denser material becomes hazier due to increased light scattering. In initial studies from 2016, both Hu and Berglund found that millimeter-thin sheets of resin-infused wood skeletons permitted 80 to 90 percent light transmission.

As the thickness approaches a centimeter, light transmittance decreases; for instance, Berglund’s group reported that 3.7-millimeter-thick wood, approximately as thick as two pennies, allowed only 40 percent of light to pass through.

Transparent wood’s slim profile and extraordinary strength position it as an ideal alternative to products crafted from fragile, thin plastic or glass, particularly in applications such as display screens.

French company Woodoo, for instance, employs a similar process to remove lignin from wood in its screens, preserving a hint of lignin for a unique color aesthetic. The company tailors its recyclable, touch-sensitive digital displays for various products, including car dashboards and advertising billboards.

Nonetheless, the primary focus of most research has gravitated towards transparent wood as an architectural marvel, with windows emerging as an especially promising application.

More To Discover

- Musk Lied About Using Terminally Ill Monkeys at Neuralink; They Died Horribly

- New Swedish ‘Electric Soil’ Boosts Barley Growth by 50% in 15 Days

- They’re Using Dirt To Power Fuel Cells! Soil-Based Microbial Fuel Cells Offer Nearly Limitless Energy

- MIT Tech Vaporizes Rocks to Go Deep For Massive Clean Energy Source

Prodyut Dhar, a biochemical engineer at the Indian Institute of Technology Varanasi, emphasizes that transparent wood outperforms glass in terms of insulation. Its ability to retain heat or keep it at bay makes it an attractive choice for buildings.

In 2019, Hu and his team even managed to incorporate polyvinyl alcohol (PVA)—a polymer used in glue and food packaging—into the wood skeletons, resulting in transparent wood that conducts heat at a rate five times lower than that of glass, as reported in Advanced Functional Materials.