3D printing has changed the game, letting us whip up complex designs easily. It started with plastic, moved on to metals, and even chocolate. But as cool as this is, it’s also led to more waste, especially with plastics that you can’t recycle. We’re in serious need of something better and more earth friendly. Turns out, wood might just be the hero we need. Imagine this: wooden partition screens and window coverings, all from a 3D printer. It’s not just cool; it might just be the shake-up the design world needs.

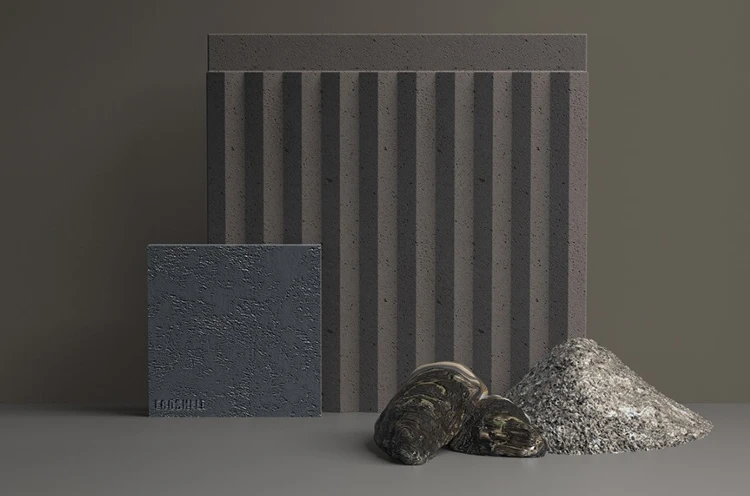

Let’s talk about why designers dig wood. It looks great, feels nice, and eventually breaks down without harming the planet. But making something fancy out of wood isn’t always easy, and once you’ve made something, it’s tough to turn it into something new. That’s where 3D printed wood comes in. This isn’t your average wood. It’s made from leftover wood bits, mixed with stuff like lignin and cellulose, and strengthened with plant fibers from flax or hemp. It’s as tough as regular wood but can do much more.

This 3D printed wood isn’t just pretending. It looks, feels, and even smells like the real deal. But here’s the kicker: when you’re done with it, you can grind it up and print something new. That means less waste and a happier planet. You’re not stuck with what you’ve got; you can keep creating new things without adding to the landfill.

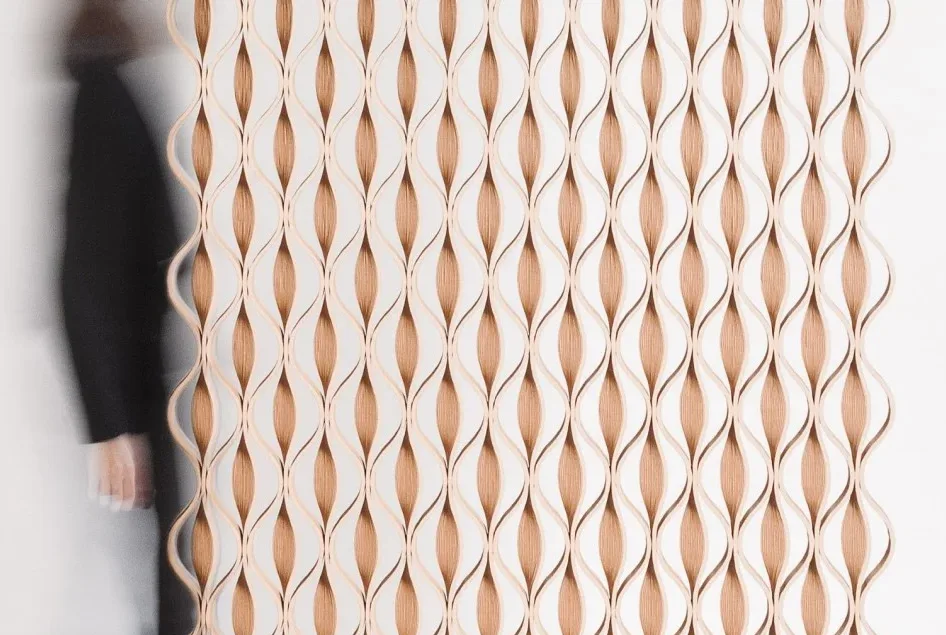

Aectual is the name behind this idea. They’re showing off what’s possible with 3D printed wood, like intricate designs and patterns that would be a nightmare to make by hand. It’s an exciting start, but let’s not get ahead of ourselves. Making this stuff isn’t cheap or easy—yet. But it’s a big step in the right direction for designers who love wood but hate waste.

While we don’t have a firm price on Aectual’s wood-printed designs, if their current offerings are any indication, expect to pay around $2,000+.

Using wood waste means we’re not chopping down more trees than we need to. Mix that with natural stuff, and you’ve got a material that’s good for the planet from start to finish. If a product’s life is over, no problem. It can be broken down and made into something new over and over. That’s way better than plastic that ends up in the ocean or a landfill.

More To Discover

It’s early days for 3D printed wood, but the potential is huge. We’re talking about a real chance to do things differently in design, where we don’t have to choose between cool designs and taking care of the planet. Aectual’s on to something, showing that you can have it all: innovation, style, and sustainability.

Meet The Designer: Aectual

Aectual is one of the world’s leading sustainable furniture & finishes platform. The Amsterdam-based company uses a circular material loop through a global network of XL 3D printers and recycling partners, allowing it to lower waste.